Spindle Control with a MOSFET

If you are not using a VFD, and your spindle motor is a DC motor of low enough power, you can control it directly using the MOSFETs on the Smoothieboard.

The power must be low enough in both voltage and current, including any current extremes when stalled.

Overview

MOSFETs are present on-board, but have limited current capacity (up to 12A).

They need to be protected by a ‘flyback’ diode when controlling a motor, electromechanical relay or other inductive load.

For more information, see:

Motors have the property of inductance, which is the electrical equivalent of inertia.

The motor current will continue to flow after the MOSFET is switched off, because the energy stored in the inductor by the current does not instantly disappear.

The current will decrease as the stored energy is dissipated.

This current flow results in the voltage across the motor reversing and increasing (or “spiking”) until the current finds a path to flow.

An appropriately connected ‘flyback’ diode with sufficient voltage and current ratings will provide a safe, intended path for the motor current.

Without a diode, when the MOSFET turns off the motor voltage will spike up until the current finds an unintended path.

Typically this degrades or immediately destroys the MOSFET and perhaps other circuitry such as that driving the MOSFET gate.

Connect the diode in reverse across the motor (when the MOSFET is on, it must NOT cause power to flow through the diode).

Connect the anode (‘arrow’) to the MOSFET Drain terminal and the cathode (‘bar’, often marked by a line on the package) to the motor power supply.

The diode rating should be rated with Voltage exceeding the maximum expected supply voltage by at least 20% (usually low cost to get a higher voltage rating).

And (conservatively) Current at least equal to half the motor current (the current through the diode will not be continuous).

An example part number is 6A4-T, rated 6A and 400V, under $1 USD.

The same considerations apply to other inductive loads such as solenoid valves and relay coils.

Solid state relays are controlled via a GPIO pin, and can control higher loads.

But are on/off only (no control of the exact amount of power sent via PWM).

For more information about SSRs, see this appendix.

Important Note

A MOSFET cannot provide power if it is not provided power via an input.

Make sure you properly connect both the input power and output connections.

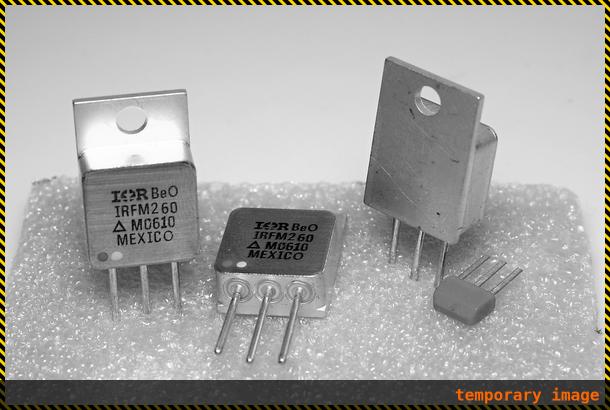

MOSFETs

MOSFETs

Smoothie has up to 6 MOSFET controls (6 on 5X, 4 on 4X, and 2 on 3X).

The MOSFETs act as switches to ground: loads must be connected between the power source and the MOSFET switched terminal.

When the MOSFET is switched on, power will be applied to the load.

When the MOSFET is switched off, power will be removed, because one load terminal will be essentially disconnected and current cannot flow.

The exception being inductive load ‘flyback’ switching transients, discussed above.

Connect your PSU to the power input connector for those FETs (providing power to the load), and connect your power-consuming element (be it heating element, spindle, etc.) between the power output terminal and the MOSFET terminal.

Smoothie connects/disconnects the element’s ground as needed to maintain temperature or as requested by G-codes.

There are three main pairs of MOSFETs on the board:

MOSFET Overview

Smoothieboard v2 has a simplified and safer MOSFET architecture compared to v1:

| Output Type | Count | Current | Purpose |

|---|---|---|---|

| Low-Current FETs | 4 | ~5A each | Hotend1, Hotend2, Fan1, Fan2 |

| Bed FET | 1 (2× parallel) | ~10-12A | Heated bed |

| SSR Outputs | 2 | Milliamps | Solid-state relay control |

All MOSFET outputs are powered from the VFET power input (2× XT30 connectors, 30A total).

Key Safety Feature: High-Side PFET Watchdog

The 4 low-current FETs share a common +VFET rail controlled by a high-side P-channel MOSFET (PFET) watchdog. The firmware can instantly kill power to all 4 outputs if a thermal runaway or fault is detected.

How it works:

- All 4 low-current FETs (hotends, fans) connect to a shared +VFET power rail

- This rail is controlled by a high-side PFET watchdog

- If any low-side FET fails shorted (stuck ON), the high-side PFET can still disconnect power

- Provides an additional layer of protection against thermal runaway

Bed FET Independence:

- The heated bed FET is NOT controlled by the high-side PFET watchdog

- This is deliberate: allows the bed to remain on even if other FETs are shut down

- Bed thermal runaway protection is handled directly by firmware

Low-Current FETs (Hotends, Fans)

| Specification | Value |

|---|---|

| Outputs | 4 (hotend1, hotend2, fan1, fan2) |

| Current Rating | ~5A per output |

| Voltage | Up to 24V |

| Power Source | Shared +VFET rail |

| Safety | High-side PFET watchdog |

| Control | PWM capable (firmware-controlled frequency) |

| LED Indicators | Yes (per output) |

Bed FET

| Specification | Value |

|---|---|

| Configuration | 2× MOSFETs in parallel |

| Combined Current | ~10-12A |

| Voltage | Up to 24V |

| Power Source | Direct from VFET (not through PFET watchdog) |

| Control | PWM capable |

| LED Indicator | Yes |

200W bed @ 12V: 16.7A - Consider using an external SSR

200W bed @ 24V: 8.3A - Within bed FET capacity

SSR Outputs

| Specification | Value |

|---|---|

| Outputs | SSR1, SSR2 |

| Type | Logic-level (3.3V or 5V signal) |

| Current | Milliamps (for SSR coil drive) |

| Use Cases | Solid-state relay control, auxiliary outputs |

Use SSR outputs to control external solid-state relays for:

- High-power heated beds (>12A)

- AC-powered heaters

- Other high-current loads

Power LED Indicators

Each MOSFET output has its own LED indicator showing when it’s active:

- Hotend1 LED: Hotend 1 heater active

- Hotend2 LED: Hotend 2 heater active

- Fan1 LED: Fan 1 active

- Fan2 LED: Fan 2 active

- Bed LED: Heated bed active

-

Big MOSFET pair: Their outputs are labeled P

2.7 and P2.5 on the schematic, the input connector for them is found between them. They are found on the 4X and 5X boards. To power those MOSFETs, you need to provide them with power by wiring their power input to the power supply. -

Small MOSFET pair: Their outputs are labeled P

2.6 and P2.4 on the schematic, the input connector for them is found by their side, between P2.6 and P1.23 . They are found on all of the boards. To power those MOSFETs, you need to provide them with power by wiring their power input to the power supply. -

Mixed MOSFET pair: Their outputs are labeled P

1.22 and P1.23 on the schematic. The pair is called “mixed” because it consists of one big MOSFET and one small MOSFET. They do not have a specific input, they take power directly from VBB (the Stepper motors power input described in the Stepper Motors chapter). To power those MOSFETs, you need to provide them with power by wiring their power input (which is the same as the one for the stepper motors) to the power supply.

This allows you to use different voltages for different things if you want, and makes it easier to use more current as the current is shared between more connectors. It does mean wiring one or two more connectors though.

If you are trying to control MOSFETs and they are not turning on, make sure you provided power to their power input.

MOSFETs list:

| MOSFET group | MOSFET name | Controlling pin | Output connector | Input method | Voltage | Current |

|---|---|---|---|---|---|---|

| Big MOSFETs | First big MOSFET | X15 | Big MOSFETs power input X13 | 12-24V | 12.5A max | |

| Big MOSFETs | Second big MOSFET | X10 | Big MOSFETs power input X13 | 12-24V | 12.5A max | |

| Small MOSFETs | First small MOSFET | X7 | Small MOSFETs power input X6 | 12-24V | 3A max | |

| Small MOSFETs | Second small MOSFET | X8 | Small MOSFETs power input X6 | 12-24V | 3A max | |

| Mixed MOSFETs | Third big MOSFET | X16 | VBB (motor) input | 12-24V | 12.5A max | |

| Mixed MOSFETs | Third small MOSFET | X9 | VBB (motor) input | 12-24V | 3A max |

MOSFETs diagram

+ on that connector to + on your PSU, and - to - on the PSU.

Heater elements, however, do not have a polarity, so you do not have to worry about polarity on the outputs.

If you are using another output element like a Peltier or a Spindle, you need to be careful to respect the polarity for the outputs too.

Never use the big MOSFETS for more than 12.5A (and monitor connector and MOSFET temperatures at that current use, too much heating can be a sign of a bad wire connection), and the small MOSFETS should never be used for more than 3A.

Trying to power a 40W (or more) hotend cartridge heater at 12V with the small FETs will destroy them, usually locking (melting) them to the “ON” state (shorted) and possibly destroying the circuitry driving the MOSFET gate.

If you need to control more than 12 Amps, you cannot do it with one of the MOSFETS on board, however, you can use a Solid State Relay.

For information see the Solid State Relay Appendix on this page.

There is an alternative, however (for currents up to 2 Amps or 4 Amps). For each pair, you can use jumpers (one jumper for the small MOSFETS pair (JP28), two parallel jumpers for the two big MOSFETS pair (JP11 and JP27)).

If you solder the pins for those OR connect a jumper to those pins, closing the circuit to VBB (the stepper motors power input), allowing you to take the power from those MOSFETS from the same place as the stepper motors do.

In the case of the big MOSFETS, you have to solder and put in place two jumpers, in parallel, in order to handle more current.

This means you cannot use this way of powering your MOSFETS if you are going to use more than 2A (for the small MOSFETS) or 4A (for the big MOSFETS, with both jumpers used, for 2 x 2A).

Do not use the jumpers to power a heated bed, for example, as it uses much more than 4A.

Wiring MOSFET Outputs

Power Connection

All MOSFET outputs on Smoothieboard v2 are powered from the VFET power input:

Unlike v1, Smoothieboard v2 has a single VFET power input (2× XT30 connectors) that powers ALL MOSFET outputs. No separate power inputs for different MOSFET groups!

Wiring steps:

- Connect your 12-24V power supply to the VFET XT30 connectors

- Connect your heaters/fans between the MOSFET output terminals and ground

- That’s it - no jumpers or multiple power connections needed!

MOSFET Output List

| Output | Type | Current | Typical Use |

|---|---|---|---|

| Hotend1 | Low-current FET | ~5A | First hotend heater |

| Hotend2 | Low-current FET | ~5A | Second hotend heater |

| Fan1 | Low-current FET | ~5A | Part cooling fan |

| Fan2 | Low-current FET | ~5A | Auxiliary fan |

| Bed | Dual parallel FETs | ~10-12A | Heated bed |

| SSR1 | Logic output | mA | External SSR control |

| SSR2 | Logic output | mA | External SSR control |

Polarity and Safety

+ on your PSU to the + terminal on the XT30 connectors.

Heater elements (resistive) do not have a polarity, so you do not have to worry about polarity on the outputs.

If you are using a Peltier element or a DC motor, you need to respect the polarity for the outputs.

High-Current Loads (>12A)

If you need to control more than 10-12A (the bed FET limit), use the SSR outputs to control an external Solid State Relay:

- SSR1/SSR2 provide logic-level signals to drive SSR coils

- Use a properly rated SSR for your load (e.g., 40A SSR for AC-powered heated beds)

- SSRs are recommended for AC mains-powered heaters

For information see the Solid State Relay Appendix.

In order to configure your Smoothieboard to use a specific MOSFET, you need to know which pin corresponds to which MOSFET.

Here is a recapitulating table to help you find that out:

MOSFETs Table

This page documents the MOSFET outputs available on Smoothieboard and their specifications.

MOSFETs are used to control high-power devices like heated beds, hotends, fans, and other accessories.

MOSFET Specifications

| MOSFET Pair | Big MOSFETS | Small MOSFETS | Mixed MOSFETS | |||

|---|---|---|---|---|---|---|

| Label on diagram | P |

P |

P |

P |

P |

P |

| Digital output pin | ||||||

| Power Input | Between P |

Between P |

Taken from VBB | |||

| Size | Big | Big | Small | Small | Big | Small |

| Maximum current | 12A | 12A | 3A | 3A | 12A | 3A |

| Used by default for | Heated bed | Hotend 0 | Fan | Hotend 1 |

Understanding MOSFET Pairs

Smoothieboard has three MOSFET pairs:

Big MOSFETs Pair (P2.7 and P2.5 )

- Current capacity: 12A each

- Power input: Shared between the two outputs (between P

2.7 and P2.5 terminals) - Typical use: Heated bed (high current devices)

- Note: Both outputs share the same power input

Small MOSFETs Pair (P2.4 and P2.6 )

- Current capacity: 3A each

- Power input: Shared between the two outputs (between P

2.6 and P1.23 terminals) - Typical use: Hotend 0 and fan (moderate current devices)

- Note: Both outputs share the same power input

Mixed MOSFETs Pair (P1.23 and P1.22 )

- Current capacity: P

1.23 : 12A, P1.22 : 3A - Power input: Taken directly from VBB (main power supply)

- Typical use: P

1.23 for Hotend 1, P1.22 for accessories - Note: These outputs use the main VBB power supply

| Output | Controlling Pin | Current Rating | Typical Use |

|---|---|---|---|

| Hotend A | ~5A | Primary hotend heater | |

| Hotend B | ~5A | Secondary hotend heater | |

| Fan 1 | ~5A | Part cooling fan | |

| Fan 2 | ~5A | Auxiliary fan | |

| Bed | ~10-12A | Heated bed (dual parallel FETs) | |

| SSR1 | Logic output | mA | External SSR control |

| SSR2 | Logic output | mA | External SSR control |

Understanding MOSFET Outputs

Smoothieboard v2 has a simplified MOSFET architecture:

Low-Current FETs (Hotend A, Hotend B, Fan 1, Fan 2)

- Current capacity: ~5A each

- Power input: Shared VFET rail (2× XT30 connectors)

- Safety feature: High-side PFET watchdog can cut power to all 4 outputs

- Note: All share the same power source, controlled by safety watchdog

Bed FET

- Current capacity: ~10-12A (dual parallel MOSFETs)

- Power input: Direct from VFET (not through PFET watchdog)

- Typical use: Heated bed

- Note: Independent of safety watchdog for bed stability

SSR Outputs

- Current capacity: Milliamps (logic level signals)

- Use: Control external solid-state relays for high-power loads

Important Safety Notes

Configuration

To configure a MOSFET output in your config file, use the appropriate pin number from the “Digital output pin” row.

Example for configuring a heated bed on P

temperature_control.bed.heater_pin 2.7

Example for configuring a hotend on P

temperature_control.hotend.heater_pin 2.4

Example for configuring a heated bed on P

[temperature_control.bed]

heater_pin = 2.7

Example for configuring a hotend on P

[temperature_control.hotend]

heater_pin = 2.4

Related Documentation

- Smoothieboard - Main board documentation

- Temperature Control - Configuring heaters

- Pinout - Complete pinout diagram

- How to Wire - Wiring tutorials and best practices

Wiring

TODO: diagram

Configuration

Now that you have located which MOSFET you are going to use for Spindle control, and what GPIO pin it corresponds to, you need to add a spindle control section to your configuration file.

We will be doing this using the Switch module.

Add this to your configuration file:

V1 Configuration (flat namespace):

# Spindle control Switch module

switch.spindle.enable true #

switch.spindle.input_on_command M3 #

switch.spindle.input_off_command M5 #

switch.spindle.output_pin 2.7 # Here we are using the first big MOSFET

switch.spindle.output_type pwm # pwm output settable with S parameter in the input_on_command

switch.spindle.max_pwm 255 # set max pwm for the pin default is 255

V2 Configuration (INI sections):

# Spindle control Switch module

[switch]

spindle.enable = true #

spindle.input_on_command = M3 #

spindle.input_off_command = M5 #

spindle.output_pin = 2.7 # Here we are using the first big MOSFET

spindle.output_type = pwm # pwm output settable with S parameter in the input_on_command

spindle.max_pwm = 255 # set max pwm for the pin default is 255

Controlling the Spindle

Now that everything is configured, you can use G-codes to control the Spindle.

You can do this either manually by sending G-codes directly to the board via serial or your host software, or add those G-codes to the beginning/end of your files.

You can choose the exact G-codes in the configuration.

Here we used the standard

If you need to choose the power (speed) of your Spindle, you can do so because the output is configured as PWM.

Simply do:

M3 S128

To set the spindle to half power/speed.

PWM values go from 0 to 255.

0 means no power to the spindle, and 255 means full power to the spindle.

Diode

Because the spindle can feed power back into the MOSFET and damage the MOSFET, you also need to wire a diode of sufficient size across the output.

See notes in the first section above.

PID Loopback Spindle Control

To get more accurate RPM control, you can use a feedback sensor.

This can be optical or a hall effect sensor, which senses the rotation of the spindle.

Smoothie then measures the real RPM of the spindle and adjusts the PWM value accordingly.

Hardware Requirements

To use this module, you need to connect your spindle to pins with proper hardware support:

- PWM output pin: any of

1.18 ,1.20 ,1.21 ,1.23 ,1.24 ,1.26 ,2.0 -2.5 ,2.26 ,3.25 - Feedback sensor pin: must be in port 0 or port 2;

2.6 and2.7 are available on smoothieboard

PID Configuration Options

| V1 Setting | V2 Setting | Description |

|---|---|---|

| Enables the spindle control module. When true, the spindle module is loaded and available for G-code control (M3/M5 commands). V1 provides a dedicated spindle module with PID control, tachometer feedback, and Modbus VFD support. V2 uses a simple switch module instance for basic on/off or PWM control (no PID or feedback). | ||

| Spindle control mode. V1 supports three types: pwm (closed-loop PID control with tachometer feedback for precise RPM), analog (open-loop PWM output for VFDs/ESCs with 0-10V or PWM inputs), or modbus (RS485 communication for Modbus VFDs like Huanyang). V2 only supports: digital (on/off relay) or pwm (variable speed, open-loop only). | ||

| PWM output pin for spindle control. Must be hardware PWM-capable ( |

||

| PWM frequency for spindle control. V1 uses period in microseconds (default 1000µs = 1kHz, frequency = 1,000,000 / period). V2 uses frequency in Hz via pwm1.frequency or pwm2.frequency settings. Most VFDs and spindle controllers work with 1-50 kHz. Check your VFD documentation for required frequency. | ||

| Maximum PWM duty cycle (0.0-1.0). Acts as both a safety limit and calibration factor. Some spindle controllers (like MC2100) require less than 100% duty cycle for maximum speed (MC2100 uses 0.85). Setting below 1.0 limits maximum spindle speed even when G-code requests full power, protecting the motor from overcurrent. | ||

| Controls spindle behavior during emergency stop. When false (recommended), spindle stops immediately on any halt condition (emergency stop, limit switch trigger) for safety. When true, spindle continues running during halts. This is a safety-critical setting - use with extreme caution. | ||

| — | Tachometer input pin for closed-loop RPM control (V1 PWM mode only). Must be an interrupt-capable pin on Port 0 or Port 2 (pin number must be 2.x or 0.x). Receives pulses from hall-effect sensor, optical encoder, or other tachometer. Used with PID controller for precise RPM maintenance. Not available in V2. | |

| — | Number of tachometer pulses per spindle revolution (V1 PWM mode only). Used to calculate actual RPM from tachometer feedback. Hall-effect sensors typically provide 1 pulse per revolution, optical encoders may provide many pulses per revolution. Essential for accurate RPM calculation in closed-loop mode. Not available in V2. | |

| — | Default RPM when M3 is issued without S parameter (V1 PWM mode only). If G-code contains "M3" without specifying speed, this RPM will be used. Default 5000 RPM. Only applies to PWM spindle type with feedback control. Not available in V2. | |

| — | PID proportional term for closed-loop spindle control (V1 PWM mode only). Controls how aggressively the controller responds to RPM error. Higher values provide faster response but may cause oscillation. Lower values provide smoother operation but slower response. Requires tuning for specific spindle. Unit is 1/RPM. Default 0.0001. Not available in V2. | |

| — | PID integral term for closed-loop spindle control (V1 PWM mode only). Eliminates steady-state error by accumulating error over time. Higher values eliminate offset faster but may cause overshoot. Set too high and system becomes unstable. Requires tuning for specific spindle. Unit is 1/(RPM × seconds). Default 0.0001. Not available in V2. | |

| — | PID derivative term for closed-loop spindle control (V1 PWM mode only). Responds to rate of change of error, providing damping to reduce overshoot and oscillation. Higher values provide more damping but may slow response and amplify noise. Often set lower than P and I terms. Unit is 1/(RPM/seconds). Default 0.0001. Not available in V2. | |

| — | Low-pass filter time constant in seconds for tachometer smoothing (V1 PWM mode only). Filters out noise and transient fluctuations in RPM measurement. Higher values provide more smoothing but slower response to actual speed changes. Lower values provide faster response but may amplify tachometer noise. Default 0.1 seconds. Not available in V2. | |

| — | Minimum RPM when spindle is on (V1 analog mode only). When spindle is enabled, speed cannot go below this value. Prevents stalling and ensures minimum cutting speed. If G-code requests speed below min_rpm (but greater than 0), this minimum will be used instead. |

|

| — | Maximum RPM at 100% PWM (V1 analog mode only). Calibrates PWM output to spindle's maximum speed. For example, if your VFD is configured for 24000 RPM maximum and you request 12000 RPM (S12000), the system will output 50% PWM. Essential for accurate speed control with VFDs and ESCs. Default 5000 RPM. Not available in V2. | |

| — | Optional digital output pin to enable VFD/power supply (V1 analog mode only). Typically connected to VFD's RUN/ENABLE input via optocoupler. Goes high when spindle is commanded on ( |

|

| — | VFD manufacturer/model for Modbus control (V1 modbus mode only). Currently only supports "huanyang" VFDs. Determines the Modbus protocol and register mapping used for RS485 communication. Huanyang VFDs must be configured for RS485 control before use: PD001=2 (run command source: communication port), PD002=2 (frequency source: communication port), PD163=1 (address: 1), PD164=1 (baud: 9600), PD165=3 (data method: 8N1 RTU). Not available in V2. | |

| — | RS485 receive pin for Modbus communication (V1 modbus mode only). Used with TX and DIR pins to communicate with Modbus VFDs. Requires RS485 transceiver chip (MAX485 or similar) between Smoothieboard and VFD. This pin receives data from the VFD. Not available in V2. | |

| — | RS485 transmit pin for Modbus communication (V1 modbus mode only). Used with RX and DIR pins to communicate with Modbus VFDs. Requires RS485 transceiver chip. This pin sends data to the VFD. Not available in V2. | |

| — | RS485 direction control pin (V1 modbus mode only). RS485 is half-duplex, so a single pair of wires is used for both sending and receiving. This pin switches the RS485 transceiver between transmit and receive modes. Typically connected to DE/RE pins on MAX485 chip. Not available in V2. | |

| — | G-code command to turn spindle on (V2 only, via switch module). Typically M3 for spindle clockwise. Can be configured to any G-code or M-code. Not needed in V1 (M3 is hardcoded). | |

| — | G-code command to turn spindle off (V2 only, via switch module). Typically M5 for spindle stop. Can be configured to any G-code or M-code. Not needed in V1 (M5 is hardcoded). |

G-code Commands

Available G-code commands for PID spindle control:

M3 - Start the spindle.M3 S5000 will start the spindle and set speed to 5000 RPM.M5 - Stop the spindle. Last set RPM is remembered and used for nextM3 command if S argument is not given.M957 - Report the current spindle speed and PWM value.M958 - Report the current PID parameters.M958 Px.xxx Ix.xxx Dx.xxx will set them (to save the new values, you need to edit config file manually).

Tuning the PID parameters

There is no PID autotuning for spindle parameters currently.

You can use the following process to manually tune the PID:

- Set dummy values with

M958 P0.0001 I0 D0 - Stop the spindle with

M5 and make sure spindle is ready to run on nextM3 command (i.e. power supply is on). - Run

M3 S100000, which should start the spindle at maximum speed. - Measure the time T it takes for the spindle to reach full speed (using your ears and a stopwatch).

- Check the maximum RPM R the spindle reaches by running

M957

Now set the parameters to:

- P = 1/R (e.g. for 10,000 RPM, set P = 0.0001)

- I = 2/(R*T) (e.g. if it took 1 second to speed up to 10,000 RPM, set I = 0.0002)

- D = T / R / 10 (e.g. D = 0.00001)

Some manual tuning may be needed after this.

Test speed changes using the