Your guide to installing Smoothieboard in a 3D printer

Probably the machine for which Smoothie is most used, due to Smoothie’s roots in the RepRap project, 3D printers are fairly simple to Smoothiefy.

This is a step-by-step guide to connecting your board to the various components of the 3D printer, configuring everything, from the beginning to actual printing.

This guide is a community effort, and this page is a Wiki. Please don’t hesitate to edit it to fix mistakes and add information, any help is very welcome.

On a typical 3D printer setup, installing a Smoothieboard will mean you do the following things:

- Read all of the guide before you start, best way to avoid mistakes

- Install some Software to talk to your board

- Install the Windows drivers if using that OS

- Connect your board via USB and practice talking to it

- Take a look at the configuration

- Upgrade your firmware to the latest version if you feel like it

- Wire your power supply and provide it with power

- Wire the power supply to Smoothieboard’s motor and mosfet power inputs

- Connect motors to the stepper motor driver outputs

- Edit your configuration to match your motors

- Test the motors, and admire your accomplishment for hours

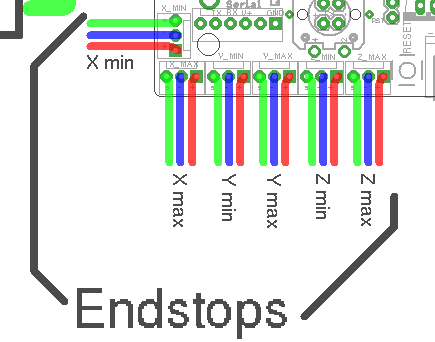

- Connect Endstops to the endstop inputs

- Edit your configuration to match your endstops

- Test your endstops by homing the machine

- Connect your hotend and heated bed’s thermistors to the thermistor inputs

- Edit your configuration to match your thermistors

- Test that they read temperature correctly, admire a beautiful temperature graph

- Connect your hotend and heated bed’s heaters to the mosfet outputs

- Edit your configuration to tell Smoothie what to heat, with what mosfet and how

- Test that you can correctly control temperature on all heaters, carefully

- Connect, configure and test any fans you may have

- Connect, configure and test any probes you may have

- Setup calibration or leveling if relevant

- Configure your slicing software and slice a 3D file into a G-code file

- Use your host software to send your new G-code file to the Smoothieboard

- Watch as the machine prints using your new Smoothieboard system

- Be happy

This guide will walk through everything you need to accomplish to successfully perform these steps.

At the end of this guide, you should have a fully working machine.

Translations

Some users have hand-translated this page. Note that this translated version is by definition never going to be up-to-date. Use it to help you understand in general, but any specific information should be taken from the original version, especially before asking the community for help.

Unboxing

Smoothieboard V1:

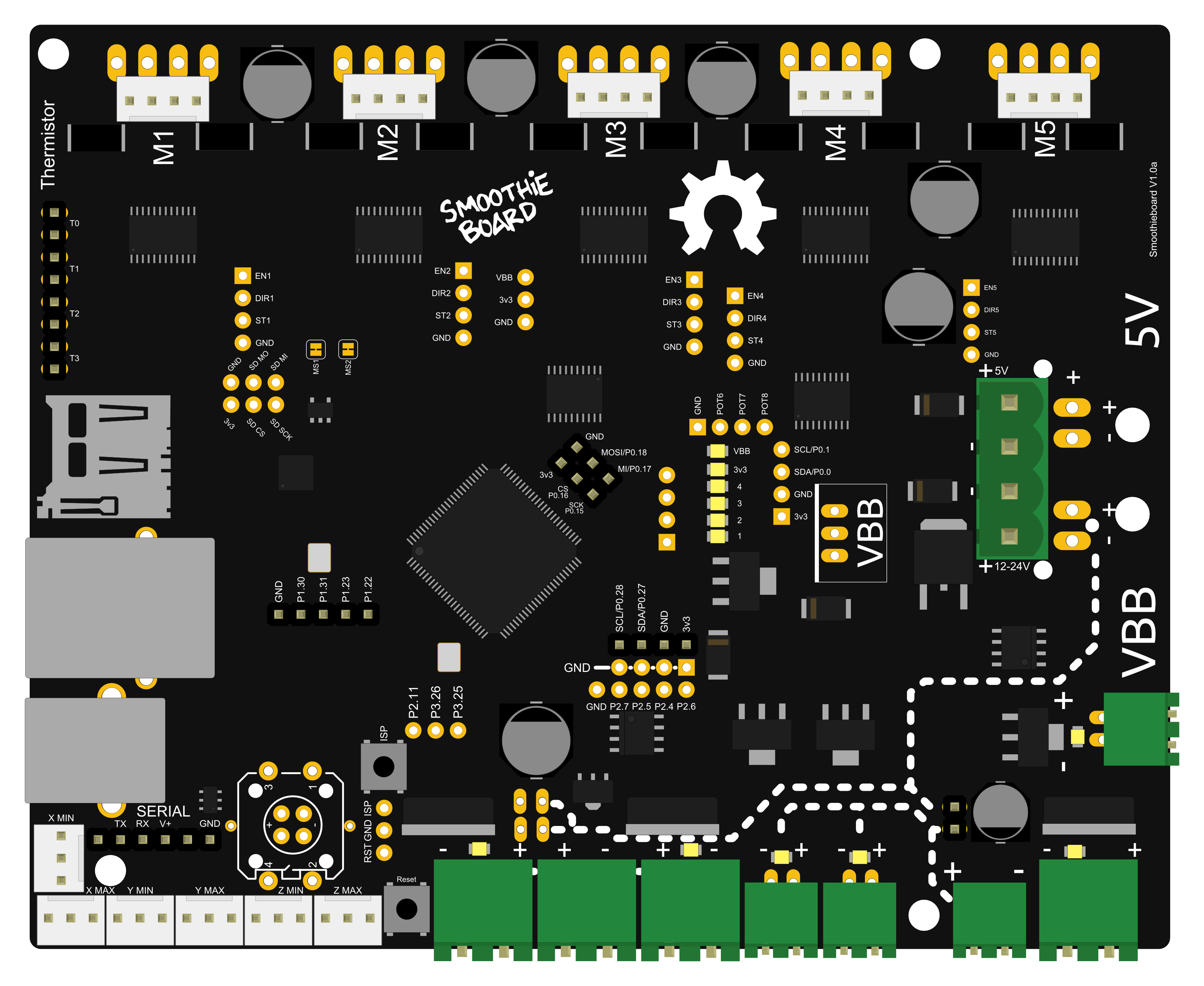

Your Smoothieboard comes with a micro SD card in the microSD slot.

The boards come pre-flashed with the latest firmware.

With a basic configuration file installed on the SD card, no preparation is needed before you can connect Smoothieboard to your computer and start interacting with it.

Smoothieboard V2 Prime:

Your Smoothieboard V2 Prime comes with an SD card (2-8 GB) in the SDIO slot, pre-loaded with firmware and a default configuration.

The boards come pre-flashed with the latest firmware.

With a default configuration file already installed on the SD card, you can connect your board immediately. The V2 also includes an onboard Ethernet port for network connectivity, which is the recommended communication method.

The first thing you might want to do before you start connecting your board is to look at our list of Software, and install a “host” program to talk to the board.

If you don't have a Smoothieboard but have or consider purchasing an MKS board, please make sure you read What's wrong with MKS

Connecting via USB

A good first step is to connect your board to your computer to familiarize yourself with it.

Connect a USB-B cable to the USB connector on the board, and to your computer.

A moment after connection, your computer will recognize the Smoothieboard as a USB Mass Storage Device (like a USB disk-drive or an SD card reader), showing you the files present on the SD card.

Drivers are needed for Windows 7/8, while Linux and Mac OS X directly support the device, you can find those drivers here.

Connect a USB-C cable to the USB connector on the board, and to your computer.

A moment after connection, your computer will recognize the Smoothieboard V2 as a USB Mass Storage Device (like a USB disk-drive or an SD card reader), showing you the files present on the SD card.

USB drivers are typically not needed on Linux, Mac OS X, or modern Windows systems. The SDIO SD card interface provides much faster transfer rates (10-25 MB/s) compared to USB Mass Storage.

This allows you to add, copy, edit, or delete any file you’d like.

Already present on the SD card is a configuration file.

This file is named “config” and contains all of the configuration options for your board in a flat text format.

The file is read when you start or reset your board.

You edit the configuration simply by editing this file in a Text Editor, saving it, and resetting the board.

This file uses INI-style sections (e.g., [actuator], [motion control]) with hierarchical settings.

The file is read when you start or reset your board.

You edit the configuration by editing this file in a Text Editor, saving it, and resetting the board. V2 configuration is structured differently from V1, so refer to the configuration guide for proper formatting.

No need to recompile or flash the board.

It can also be used to store and play G-Code files, see Player.

USB Mass Storage is not the only thing you get when you connect the board.

The board also exposes a USB CDC Serial interface, allowing you to send G-Code and receive answers.

(There is also a DFU interface for flashing firmwares but that’s mostly for developers).

The CDC (Serial) interface is the interface host programs like Pronterface use to allow you to interact with your machine.

If you are already familiar with it, you can try connecting right now and get an answer from the board.

If not, we explain it all later in this guide.

Connecting via the network

V1 Network (Optional):

The Smoothieboard V1 can optionally be connected to an Ethernet network via USB-to-Ethernet adapter or external network expansion.

This allows you to access a web interface the board can serve, and control the machine via your browser.

It also allows you to connect software that supports it (like Pronterface and Visicut) via the network.

Network connectivity is optional and disabled by default, but is easy to enable and configure if you have the appropriate hardware.

V2 Network (Built-in):

The Smoothieboard V2 Prime includes an onboard Ethernet port (RJ45) with integrated PHY, allowing direct connection to your local Ethernet network via standard network cable.

This allows you to access a web interface the board serves, and control the machine via your browser.

It also allows you to connect software that supports it (like Pronterface and Visicut) to your Smoothieboard via the network.

Network is disabled by default but is very easy to enable and configure. It is the recommended primary method of communicating with your V2 Smoothieboard.

You can find all the information you need about using the network interface here: Network interface

Updating your firmware

Before starting, a very good idea is to ensure you have the latest firmware version.

V1 Firmware Update (SD Card Method):

- Download the latest

firmware.binfile - Copy it onto the SD card

- Reset the Smoothieboard

The new firmware will “flash” (you will see the LEDs on the board do a little “dance”), and you will then have the latest version.

This is particularly useful if you ever need to ask for help, as people helping you will be assuming you have the latest version.

You can find the file, and information on how to flash it, at Flashing Smoothie Firmware.

V2 Firmware Update (Multiple Methods):

Method 1: SD Card (Recommended for first update):

- Download the latest

firmware.binfile - Copy it onto the SD card

- Reset the Smoothieboard V2

The new firmware will “flash” (you will see the LEDs on the board do a little “dance”), and you will then have the latest version.

Method 2: Network Update (requires Ethernet): Once you have network configured, you can update directly via the command:

update http://example.com/firmware.bin

This is particularly useful if you ever need to ask for help, as people helping you will be assuming you have the latest version.

You can find the file, and information on how to flash it, at Flashing Smoothie Firmware.

Migrating to Smoothie

If you are migrating from another firmware, here are guides to help you understand how some values from your old firmware match the values in your new Smoothie system.

Smoothie uses different configuration parameters and approaches than other common CNC/3D printer firmwares. These guides will help you translate your existing settings.

Migration Guides

Choose the guide that matches your current firmware:

- Moving from Marlin to Smoothie - For users coming from Marlin (common in 3D printers)

- Moving from GRBL to Smoothie - For users coming from GRBL (common in CNC mills and laser cutters)

For detailed information about configuration format differences between V1 and V2, choosing the right version, and common migration pitfalls to avoid, see the Migration Details page.

Safety Warnings

Before you start wiring your machine’s elements to the board, there are several things you need to keep in mind and be careful about during all of the assembly.

Make sure you read this. Seriously. Not kidding. Do it. It’s important.

Polarity

Always make sure the polarity is correct when wiring in power inputs (coming from the Power Supply). Reversed polarity can damage or destroy all or part of your board.

Polarity is indicated on the board itself by the + and - signs. Double check.

On older versions of the board, markings are partially hidden by the connector, making it confusing. Rely on only the diagrams.

How to check polarity: Attach your multimeter probes to the two wires of your power source respectively. If the voltmeter reading is positive it implies that the red probe is connected to the positive wire (+) and the black probe to the negative wire (-).

The main (labeled VBB) power input has a reverse polarity protection, however, it will not hold forever. As soon as you notice something is wrong, turn the power supply off and check again.

Disconnecting Stepper Motors

Never disconnect or connect stepper motors from the stepper motor drivers while the board is powered (i.e., when the Power Supply is turned on).

The drivers have very good protection against most possible problems and are very hard to destroy accidentally. But it is possible.

Preventing Shorts

Be careful that nothing metallic ever touches the board while it is powered on. Falling screwdrivers, nuts and bolts can cause shorts and destroy the board.

- Check the board before powering it on

- Do not press the reset button with anything metallic, as you could slip and cause a short

- Use a plastic screwdriver or the like

Using the Right Connector

Always check the schematic before connecting power sources (coming from the Power Supply) to the board. Connected to the wrong connector can destroy components.

A common example of this problem is plugging a power input cable into the connector for an output, or plugging the limit switches in backwards.

Crimping Quality

Make absolutely sure of your connections using crimps or screw terminals, from wires to any type of connector, are very careful and well done.

Connections (to the stepper motors for example) lost while the machine is running can destroy your board.

VBB Power Input Markings

In the case of the VBB power input, be careful. If your board came with connectors pre-soldered, the 5mm connector is present, and the polarity of that connector is that of the large traces in the wiring diagram to the right (red is +, blue is -).

On some boards, the marking on the boards may be hidden by the connector itself, so for VBB, do not rely on the markings on the board, but on the diagrams on this page.

However, if you did not get your connectors soldered, and want to solder a 3.5mm connector instead of a 5mm connector, also note that the polarity is the opposite.

USB vs Ethernet

USB can, in some setups, be subject to interference, which causes disconnections, and can ruin your work. This is very hard to prevent if it happens even in normal conditions.

Ethernet, on the other hand, does not have this problem: save yourself the trouble, and use Ethernet right away. It's very nice. See Network for information on how to set it up.

How to Destroy Your Board (Don’t Do These Things)

If you receive a bad board, you will get a replacement. But if you destroy your own board, your only options will be to fix it yourself (which can be quite difficult), or get a new one.

This is why it is very important you make sure you do not destroy your own board. Smoothieboard is reasonably protected, but there are still things that will destroy it.

The general idea is: if a part of the board gets too much power, it will get destroyed.

Common mistakes that cause board destruction:

- Plugging 12-24v (motor power) into anything you are not supposed to. Like the 5V line, or an end-stop or thermistor input for example. Problems with the 5V or 3.3V power are not as much of a problem as the board is 5V-tolerant, so wrong connections and shorts should be okay as long as they do not last too long.

- Shorting 12-24v to anything else, which is essentially the same as plugging it into a place you are not supposed to (see above). This can happen by dropping a metal object onto the board, bad soldering, loose wires, un-protected wires, etc ...

- Using an inductive load (like a motor, fan or solenoid) on a MOSFET, without a diode across (see Fan documentation).

The general idea here is: always make sure everything is clean, and double-check everything before turning the power on. You can not learn by making mistakes here, as mistakes will likely cost you your board.

Electrostatic discharge can also destroy your board: make sure you properly ground everything.

Heater Safety

If your machine contains any heating element and uses the temperature control module to control it, please make sure you read the section about implementing all safety measures here, and implement as many as you can.

Fires will kill you if you don't.

Grounding

Make sure your machine's case and electronics are properly grounded, also make sure your location's electrical installation's grounding is correctly done.

Grounding Resources:

Environmental Hazards

It's not just the machine itself that can be dangerous:

Laser Cutters: The machine vents large quantities of toxic smoke and gas, make sure it is very well evacuated to a place where no-one is breathing them

CNC Mills: Dusts, like wood dust for example, can be explosive if they come in contact with a flame, be careful and take measures to limit dust in the air

3D Printers: The acetone used to clean things is very flammable, and the sprays used to increase bed adherence are explosive, store them adequately and be careful when using them

Confined Spaces: You are even more in danger if you are using your machine in a confined space, always be on the watch for safety issues.

Further Reading

For a good read about safety, you can refer to the RepRap Wiki documentation on the subject.

To properly understand some of the safety instructions in this documentation, basic knowledge about electricity is required. See this page for a refresher on the basics.

Summary

- Always check polarity before connecting power

- Never disconnect motors while powered

- Keep metallic objects away from powered boards

- Double-check all connections before powering on

- Ensure quality crimps and connections

- Use Ethernet instead of USB when possible

- Implement all heater safety measures

- Properly ground your machine and workspace

- Be aware of environmental hazards

- When in doubt, power off and check

Remember: Prevention is always better than repair. Take your time, double-check everything, and never skip safety steps to save time.

Logic Power Inputs

There are different ways of providing logic power to your board.

Your board needs two sorts of power to work:

- 12-24V power to turn motors, heat hotends, etc.

- 5V (or “logic”) power to power the microcontroller (the brain)

Three Ways to Provide 5V Power

There are three ways to provide 5V power to the board:

1. Via USB cable

USB cables provide 5V directly to the board.

This is the simplest method and works well for testing and setup.

2. Via voltage regulator

By soldering a voltage regulator to the board (and providing 12+24V, which the voltage regulator then turns into 5V).

This allows the board to be powered from your main power supply.

3. Direct 5V input

By providing 5V directly to the 5V power input (next to the VBB power input).

This requires a separate 5V power supply.

Simplest Solution

If you want to keep it simple, the easiest solution is just to connect your Smoothieboard to your computer via USB.

Multiple Power Supplies

Smoothieboard has diodes on-board that will simply get the power from the one with the highest voltage.

This means you can even turn one off and the other will be used without a reset.

Understanding Voltage and Current

If voltage and current are strange concepts to you, it’s probably a good idea before you continue setting up your board, that you read this introduction.

Power Consumption

The board’s logic circuits (5V line) typically consume up to 500mA current (what is standard for a USB port).

Your board needs two sorts of power to work:

- 12-24V power to turn motors, heat hotends, etc.

- 5V (or “logic”) power to power the microcontroller (the brain)

Three 5V Power Sources

Smoothieboard v2 supports three different 5V power sources, with automatic switching between them:

1. Onboard 5V Regulator (Recommended)

The board has a built-in 3A switching regulator that converts your motor power (Vmot, 12-24V) to 5V.

| Specification | Value |

|---|---|

| Output Current | 3A continuous |

| Input Source | Vmot (12-24V) |

| Efficiency | 85-90% (switching regulator) |

| Disable Jumper | JP16 (near OSHW logo, top side) |

This is the preferred power source for most setups. It provides enough current to power:

- The board itself (~300-500mA)

- A Raspberry Pi (~500-1500mA)

- A small touchscreen (~400-700mA)

Using the onboard regulator means you only need one power supply (12-24V) for your entire system - no separate 5V supply required!

2. USB Power

USB provides 5V directly to the board, limited to ~500mA (USB specification).

| Specification | Value |

|---|---|

| Output Current | ~500mA (USB spec limit) |

| Disable Jumper | JP15 (bottom side, near 5V input) |

This is useful for:

- Testing and initial setup

- Low-power configurations

- When Vmot is not connected

If you're connecting a Raspberry Pi to the board via USB, you may want to cut the JP15 jumper to prevent the Pi from attempting to power the board through USB (which could cause issues).

3. External 5V Input

You can provide 5V directly via the dedicated 5V input header.

| Specification | Value |

|---|---|

| Connector | 5Vin header |

| Current Capacity | Depends on your external supply (2-5A recommended) |

This is useful when you:

- Have a dedicated 5V power supply

- Need more than 3A for peripherals

- Want to keep 5V power independent from motor power

Automatic Power Source Selection

You can connect multiple 5V sources simultaneously! The board automatically selects the best source.

Smoothieboard v2 uses ideal diode ORing for automatic power source selection:

- Automatic switching: The board selects the source with the highest voltage

- Backflow prevention: Power cannot flow backward between sources

- Minimal voltage drop: Only ~tens of mV loss (vs ~600mV with standard diodes on v1)

- No manual switching: Connect everything, and it just works

Typical priority order:

- Onboard regulator (if Vmot present)

- External 5V input

- USB power (if jumpers intact)

This means you can turn off one power source and the board will seamlessly switch to another without resetting!

Power Status LEDs

Smoothieboard v2 has several LEDs to help you monitor power status:

| LED | Indicates |

|---|---|

| Vmot LED | Motor power present (12-24V) |

| Vfet LED | MOSFET power present (12-24V) |

| 3.3V LED | Logic power present (board is on) |

| MSD LED | Mass Storage Device mode active |

| Debug LEDs | 4× programmable status LEDs |

Disabling Power Sources with Jumpers

You can physically disable individual power sources by cutting jumpers:

- JP15: Cut to disable USB 5V input (useful when connecting Raspberry Pi via USB)

- JP16: Cut to disable onboard 5V regulator (if using external 5V supply exclusively)

Most users should leave all jumpers intact. Only cut them if you have a specific reason (like preventing USB backfeeding from a Raspberry Pi).

Understanding Voltage and Current

If voltage and current are strange concepts to you, it’s probably a good idea before you continue setting up your board, that you read this introduction.

Power Budget Example

Here’s a typical power budget for a 3D printer with Raspberry Pi:

| Component | Current @ 5V |

|---|---|

| Board logic | ~300-500mA |

| Raspberry Pi 3 | ~500-1500mA |

| 7” touchscreen | ~400-700mA |

| Total | ~1.2-2.7A |

The onboard 3A regulator handles this comfortably with headroom to spare!

Main Power Input

Without power, your board cannot do much.

The board uses power to operate the control logic, move stepper motors, power heating elements, fans, and other peripherals.

How to choose a power supply unit (PSU)

Two power supplies are required, 5.0V and ‘bulk’ power (VBB).

5.0V supply

- Voltage (V): The 5.0V supply should be regulated to 5% tolerance (4.75V to 5.25V). This supply provides power for the control logic circuitry, and should be a good quality regulated power supply (which is inexpensive). Using a cheap buck regulator from a higher voltage is not recommended, as ever exceeding 5.5V on this supply may instantly and permanently damage the control logic on your Smoothieboard.

- Current (A): The 5.0V supply should be rated to supply at least 1A continuous current (or more). Typical load is roughly 0.5A.

VBB supply

- Voltage (V): VBB can be from 12 to 24V. While most of the components on the Smoothieboard are rated up to 32V, it is not recommended or supported to use that high of a voltage. 12V PSUs are more common, and generally cheaper. However, the higher the voltage, the higher performance you can get from your stepper motors. This is the reason some designers use 24V PSUs. However, be careful that with a 24V PSU, you will need 24V fans, and will need to reduce the PWM setting for your heating elements or (preferred, and safer) use 24V heating elements.

- Current (A): The total current required is the current for each stepper motor, plus the current for every peripheral on your machine Smoothieboard will control. This depends on your machine type. On a typical 3D printer, you can safely consider 10A to be sufficient for the heated bed, and 10A or a bit less for the rest of the loads. Go for a 17 to 20A PSU if you have a heated bed. 7A to 10 is probably enough if you do not have a heated bed (or if you are setting up a CNC mill or a laser cutter). If you bought your machine as a kit, a PSU with appropriate current is most probably provided (or one is recommended). If building your machine yourself by self-sourcing, the documentation for the machine model will also most probably recommend a current rating. A power supply that is able to supply more current than is needed is not a problem. Having not enough current to drive your hot-end, heater bed, or motors is a problem.

Power Architecture Overview

Smoothieboard v2 uses a dual power architecture that separates motor power from MOSFET (heater/fan) power. This provides better current handling and more flexibility.

| Power Domain | Connector | Voltage | Purpose |

|---|---|---|---|

| Vmot | 1× XT30 | 12-24V DC | Stepper motors + 5V logic regulator |

| VFET | 2× XT30 | 12-24V DC | All MOSFET outputs (heaters, fans) |

| 5V | Built-in | 5V DC | Logic power (from Vmot regulator) |

Unlike v1, Smoothieboard v2 has a built-in 3A, 5V switching regulator. You typically only need a single 12-24V power supply for everything!

How to Choose a Power Supply Unit (PSU)

Vmot (Motor Power)

| Specification | Value |

|---|---|

| Connector | XT30 |

| Voltage Range | 12-24V DC (24V recommended) |

| Powers | Stepper motor drivers + onboard 5V regulator |

| Typical Current | 5-15A depending on motors |

- 24V is recommended for better stepper motor performance (higher top speed, less heating)

- Components are rated to 32V, but 24V maximum is supported

- The onboard 5V regulator draws from Vmot, so ensure your PSU can handle motor current + ~1A overhead

VFET (MOSFET Power)

| Specification | Value |

|---|---|

| Connectors | 2× XT30 |

| Voltage Range | 12-24V DC |

| Current per Connector | 15A continuous |

| Total Current | 30A combined |

| Powers | All heaters, fans, SSR outputs |

Why 2× XT30 instead of 1× XT60?

- Lower vertical profile (fits in enclosures better)

- 12V heated beds draw high current and need both connectors

- 24V systems often only need one connector

12V heated bed (200W): 16.7A → Requires BOTH XT30 connectors

24V heated bed (200W): 8.3A → Single XT30 sufficient

Power Budget Examples

Typical 24V 3D Printer:

| Component | Current @ 24V |

|---|---|

| 4× Stepper motors (1.5A each) | 6A |

| Heated bed (250W) | 10.4A |

| 2× Hotends (80W total) | 3.3A |

| 2× Fans (10W total) | 0.4A |

| Board logic + peripherals | ~2A equivalent |

| Total | ~22A |

Recommended PSU: 24V, 25-30A (600-720W)

Typical 12V 3D Printer:

| Component | Current @ 12V |

|---|---|

| 4× Stepper motors (1.5A each) | 6A |

| Heated bed (250W) | 20.8A |

| 2× Hotends (80W total) | 6.7A |

| 2× Fans (10W total) | 0.8A |

| Board logic + peripherals | ~4A equivalent |

| Total | ~38A |

Recommended PSU: 12V, 40-50A (480-600W)

Notice how 24V systems draw roughly half the current for the same power. This means smaller wires, less heat, and often cheaper power supplies!

5V Logic Power

The onboard 3A switching regulator provides 5V logic power automatically when Vmot is connected. See Logic Power for details on alternative 5V sources.

General Notes

Multiple-output power supplies are available. In some cases, a minimum load must be applied to the primary output before the secondary output will be regulated to within tolerances. For example, a dual 5.0V and 12V supply might regulate the 5.0V well at no-load conditions, but the 12V output may be low until power is drawn from the 5.0V supply.

EMI Filtering

Electromagnetic Interference (EMI): Digital logic and power circuitry (such as stepper motor drivers) switches currents and voltages on and off very rapidly. This produces EMI proportional to the voltage, current and rate of switching. EMI can be radiated (as radio waves) and/or conducted through the power line cord or other connections. EMI can interfere with (produce noise in or prevent proper operation of) other equipment, including sensors and motion encoder modules. To reduce these effects, an EMI filter module may be added to help reduce the conducted emissions. An EMI filter module may not strictly be needed, however it is often simpler to take protective measures from the start rather than e.g. searching for the cause of strange, intermittent behavior or coming back to failed 3D prints for months – and then put in an EMI filter module.

Fuses / Circuit Breakers

A typical US AC wall outlet provides 110V to 120V and is protected by a fuse or circuit breaker with a 15A or 20A rating. As (for example) a motor load such as a refrigerator or saw briefly draws a much higher starting current, in order to avoid ‘nuisance trips’ a 20A rating does not instantly remove power when that load is exceeded.

A VBB power supply rated (for example) 12V at 10A can provide up to 12V x 10A = 120W (Watts) of DC power. Power supplies are not 100% efficient, thus it will require 5% to 30% more than 120W of input power to produce 120W of output power. It is usually safe to assume at least 70% efficiency at full load (higher for more modern supplies), so the power supply will only need perhaps 1.5A at 120VAC input. A 1A, 5V supply will require much less than 1A at 120VAC input.

While the equipment can only use perhaps 2.5A, the AC wall outlet will provide at least 15A to 20A continuously without tripping the circuit breaker or blowing the fuse. It would be possible (though rare) for a fault condition that drew for example 10A at 120V = 1200W to occur, which would be a fire hazard, without tripping the breaker. If you wish to address this possibility, adding an additional fuse and/or circuit breaker with (for example) a 3A rating in line with the AC ‘hot’ wire will ensure that if there is a lot of excess power being drawn due to a circuit failure, then this fuse will blow or circuit breaker trip, and power will be removed. Too low a fuse or circuit breaker rating will result in ‘nuisance’ trips.

Setup

Make sure you use a Regulated Power Supply, make sure you connect the ground wire for the mains to the power supply, and if it has a fan, make sure it has sufficient space around it to let air flow and cool it appropriately.

To wire the power supply unit to mains (wall AC power), make sure you connect the right colored wires to the right connectors on the PSU. The 3 connectors are “live”, “neutral” and “ground”. Color changes from cable to cable. You can find charts for your specific country/cable on the internet, but the following colors are the most common:

| Standard | Load/live color | Neutral color | Earth color |

|---|---|---|---|

| US | Black | White | Green |

| Europe | Brown | Light blue | Yellow/Green |

Once the wires connected to the PSU, make sure none of your computers is doing something important (like a system upgrade). In case something goes wrong, plug the PSU into a power strip with an on/off button. Then turn that button ON. If your house loses power, you did something wrong. If an LED illuminates on the PSU, everything is fine: unplug the PSU and continue.

If you are new to wiring, please check our how to wire guide.

NEVER manipulate mains (220/110V) power wires while they are plugged into the wall plug.

Unpleasantness and/or death are common consequences of not respecting this rule.

Ground your printer's frame by connecting it to the Earth terminal on your power supply.

In the (unlikely) event that a power supply wire comes undone and touches the printer's frame, this will prevent you from getting an unpleasant and/or deadly shock.

Now that the PSU is getting mains power, your PSU is converting it into 12V or 24V DC (Direct Current) power. You need to connect wires from it to the Smoothieboard to provide power.

The most important thing for DC is to respect polarity: + goes to +, - goes to -. On the PSU, + terminals are indicated as +, V+, 12V+ or 24V+. Ground (-) terminals are indicated as -, V-, COM or GND.

On the Smoothieboard they are indicated simply as + and -.

Wiring Diagram: Refer to the Smoothieboard power connection diagram for visual reference on connecting power supplies.

By convention, black (sometimes brown) wires are used for ground, and red (sometimes orange, white or yellow) wires are used for power connections.

You may want to turn on the power supplies and test the output voltages before connecting them to the Smoothieboard (and turn them back off before connecting).

Once the wires are correctly connected, you can turn the PSU ON. If everything was done correctly, the red LED (marked VBB) on the Smoothieboard will light up brightly.

If the VBB LED does not light up, immediately turn the PSU off.

Check polarity, and check all the connections are strong and properly done.

When you turn the PSU on, make sure you are ready to immediately turn it back off.

Now that the board has power, you can use that power to move things!

Emergency stop

It is recommended you setup an emergency stop button on your machine, so that in case of a problem, you can easily and quickly turn the machine off. For information on how to do this, please read EmergencyStop.

Stepper Motors

A bit of theory:

« A stepper motor (or step motor) is a brushless DC electric motor that divides a full rotation of the motor into a number of equal steps. The motor’s position can then be commanded to move and hold at one of these steps without any feedback sensor (an open-loop controller). » (Wikipedia)

Because they work by steps, and you can accurately control how many steps you move in each direction, stepper motors are a very practical way of moving things to a desired position. This makes them great for most CNC applications.

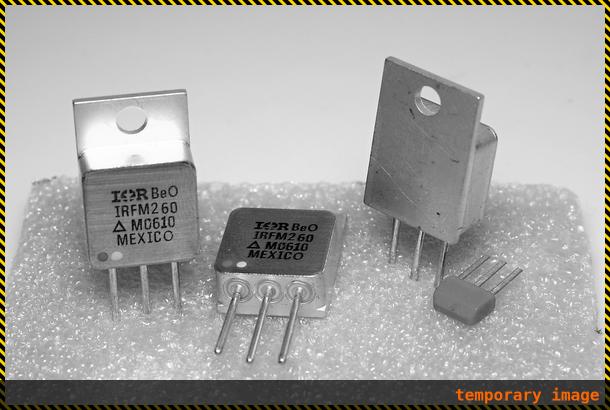

Smoothie comes with stepper motor drivers designed for bipolar stepper motors, with a maximum current rating of 2 Amps.

There is a very wide variety of stepper motors around. Bigger motors are generally more powerful.

For a given size, motors will have different torques, max speeds, and different capacities to maintain torque as speed increases. It is important you choose the right motor for your application.

The most common mistake is to choose a high inductance motor.

There are two main "families" of motors out there: high inductance motors are mostly designed for maintaining position and moving rarely (like on a telescope mount), and low inductance motors are designed for moving often, and at high speeds (like on a CNC mill or 3D printer).

If you use a high inductance stepper motor with a Smoothieboard (or any "CNC" stepper motor driver), not only will you get bad speed/torque performance, but when moving the stepper motor (or axis) by hand, very high voltage will be generated, which can destroy your stepper motor driver.

You can recognize a "high inductance" stepper motor by the fact that it's rated inductance is high, in general higher than

10mH is bad.

If your motor doesn't tell you its inductance, rated voltage is also an indication: high inductance stepper motors usually have high rated voltages, a typical value being

12V, where "CNC" steppers have voltage below 5V.

This is not what you want, you want a low inductance stepper motor, with an inductance ideally below 10mH, and a rated voltage ideally below 5V.

The reprap community defines a good stepper motor like this: Ideal stepper is (for reprap printers and similar small CNC using microstepping drivers on 12-24v supply) NEMA17 size, rated 1.5A to 1.8A or less, 1-4ohm winding resistance, 3 to 8 mH, 62oz.in (0.44Nm, 4.5kg.cm) or more of torque, 1.8 or 0.9 degrees per step (200/400 steps/rev respectively), for example the kysan 1124090/42BYGH4803 or the rattm 17HS8401 or Wantai

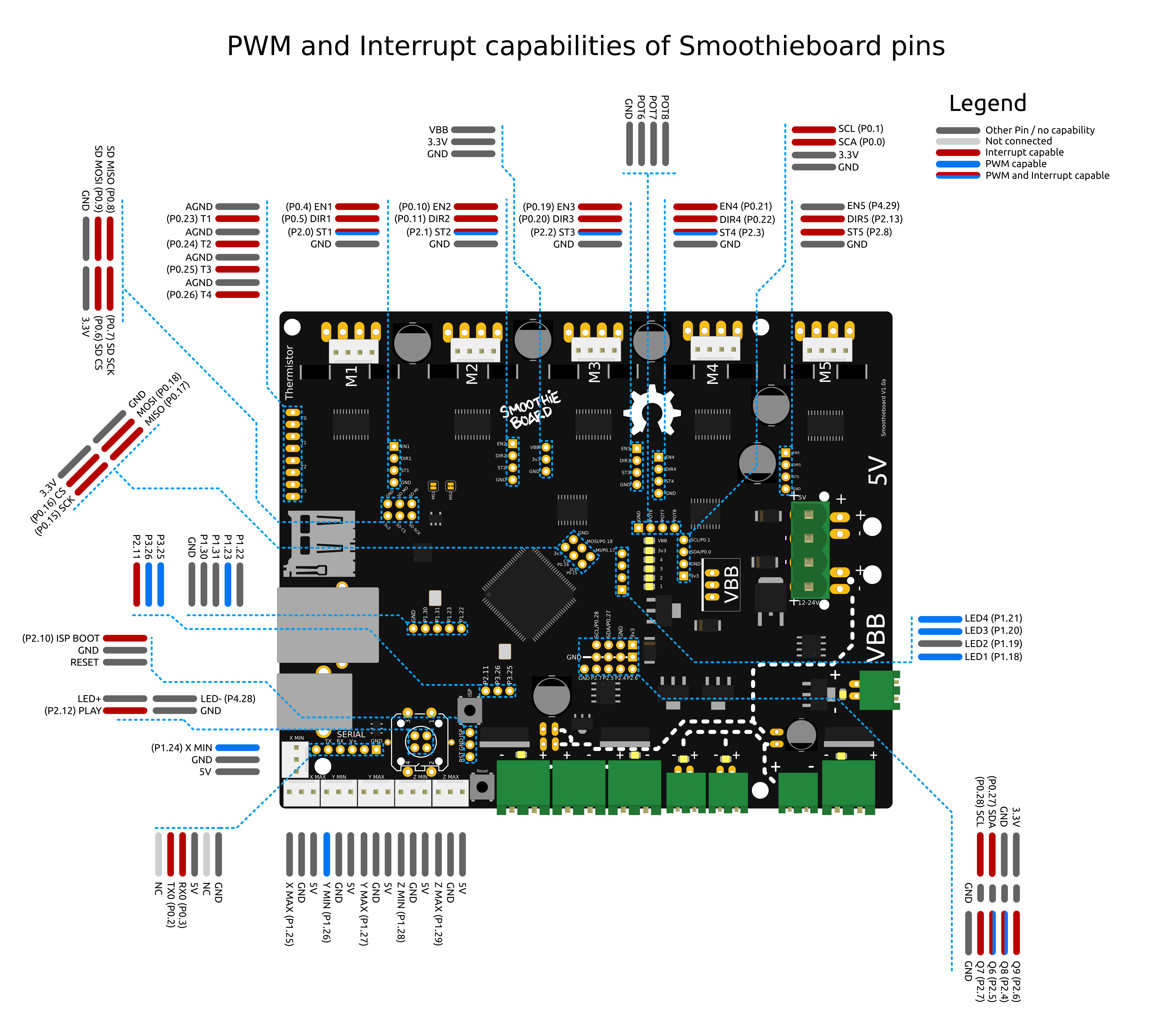

See: Stepper motor wiring - Be careful you get the coils right.

Wiring

Direct wiring

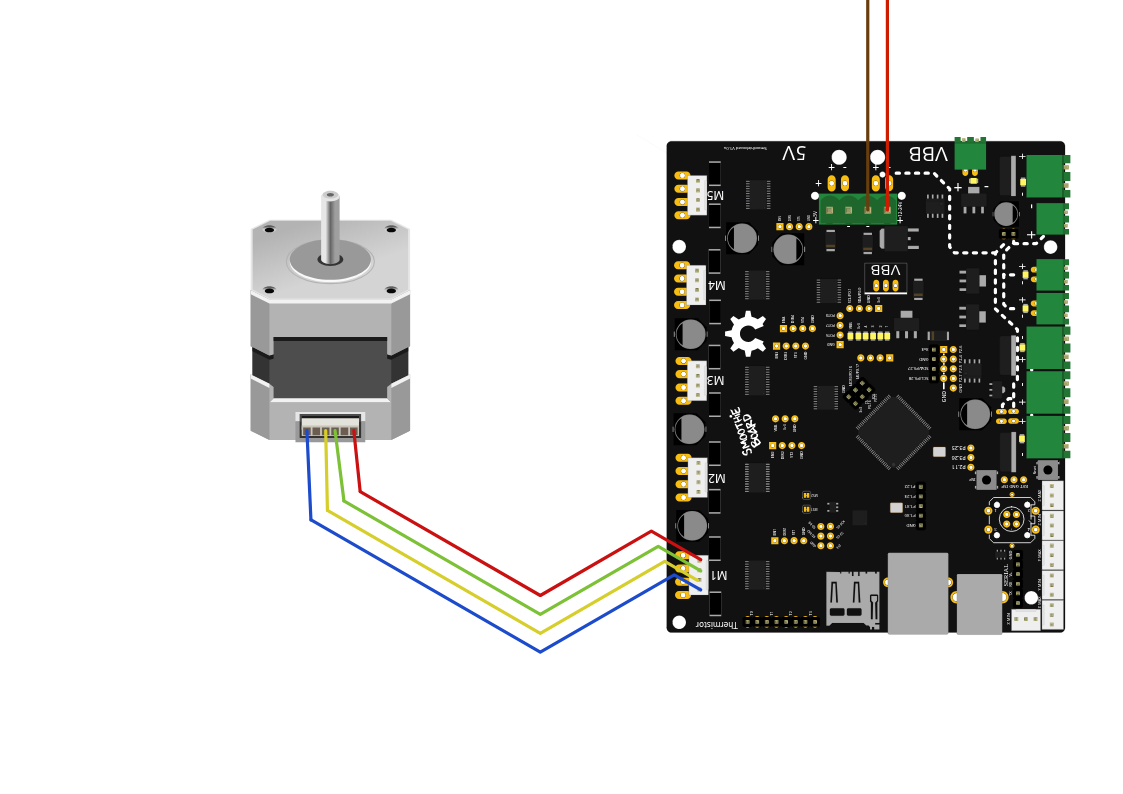

Bipolar stepper motors have two poles (bi-polar). Each pole is connected to two wires. That’s 4 wires coming out of your stepper motor. These have to be connected to your Smoothieboard.

Each stepper motor driver on the Smoothieboard has 4 connections to that effect. (Stepper motor drivers are labeled M1, M2 etc…)

The tricky thing is often to find out which wires connect to which poles. If you just wire things at random, you have a chance it will work, but let’s be scientific about it. Several methods:

- Documentation: Look at your motor, find its part number. Then google it. If you are lucky, you will find a schematic or a data-sheet that will indicate which wire goes to which pole. Note the colours that correspond to each coil.

- Fingers: When the two wires for a given pole touch together, a closed circuit for that pole is created. This makes the stepper motor more difficult to turn. You can use that effect to discover the poles. Turn the stepper motor shaft, it should turn freely. Now take two wires, and make them touch. Turn the shaft again. If it shows resistance, is harder to turn, you found a pole. If it doesn’t, keep one wire, and try another one for the second one. Do this until you find a combination that shows resistance. Once you find the two wires for a given coil, the other two wires are simply the other coil. Note the colours that correspond to each coil.

- Multimeter: Configure your multimeter to read resistance. Then the method is the same as the previous one, take two wires at random, test them, except you know you find a coil when you measure electrical resistance between two wires. If you measure no contact, try another wire combination. Note the colours that correspond to each coil.

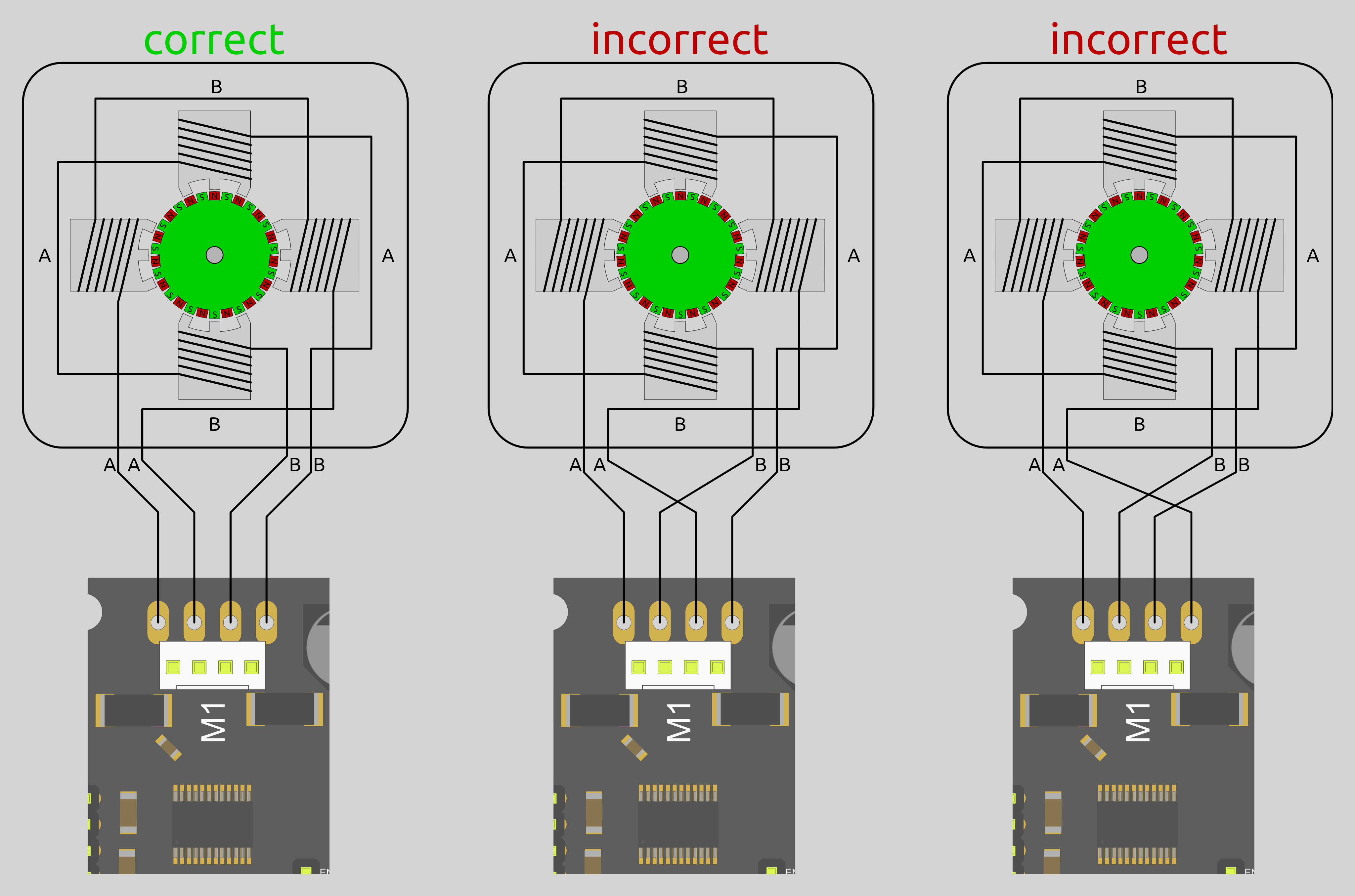

Now to connect the wires to the Smoothieboard. Let’s call one coil A, and the other coil B. It doesn’t matter which is which. Polarity also doesn’t matter, all it changes is the direction the motor turns, and you can change that in the configuration file. Now simply connect your two wires to the Smoothieboard’s 4 pins for that stepper motor driver as such: AABB or BBAA. Other combinations like ABBA or ABAB will not work.

Once your stepper motor is properly connected to your Smoothieboard, it is ready to be controlled.

In this example, a stepper motor is connected to the M1 driver, and power is provided to VBB (the main power input).

External Stepper driver

If you want to use larger stepper motors than the Smoothieboard’s drivers can handle (2A max), you need to use external stepper drivers.

You can find detailed information on how to wire an external stepper motor driver to a Smoothieboard in the External driver appendix.

Configuring

Example configurations are available on GitHub.

You can also refer to the Configuration documentation.

Current

The first thing you have to do is tell the stepper motor drivers what is the current rating for your stepper motors is. To drive the stepper motor correctly, the driver has to know the motor’s current rating.

Each stepper motor model has a precise current rating. You can drive your stepper motor at a lower current, which will make it more silent, but also less powerful. But you cannot drive the motor at a higher current than it is rated at. This would cause overheating, and possibly skipped steps.

The rating is often written on your stepper motor’s label (see picture on the right). If it is not, you can get it by googling the stepper motor model number, or by contacting your seller or manufacturer.

Once you have the correct rating, you can set the corresponding parameter in the configuration file.

Smoothie has a funny way of naming stepper motor drivers. Instead of naming them X, Y or Z, because this makes no sense in non-cartesian robots like delta robots, we name the drivers using Greek letters so they are arm application agnostic:

| Label on the Smoothieboard | Axis in a Cartesian machine | Greek letter | Current setting configuration option |

|---|---|---|---|

| M1 | X (left-right) | α (alpha) | |

| M2 | Y (front-back) | β (beta) | |

| M3 | Z (up-down) | γ (gamma) | |

| M4 | E0: First extruder | δ (delta) | |

| M5 | E1: Second extruder | ε (epsilon) |

Now, as described in the “Unboxing” paragraph, connect the board to your computer, open the “config” file with a text editor, and change the configuration value for each stepper motor driver to the correct value.

For example, if your alpha stepper motor has a current rating of 1.68A, edit the corresponding line to read:

alpha_current 1.68 # X stepper motor current

[current control]

alpha.current = 1.68 # X stepper motor current

Do this for each stepper motor you have to connect to the board. (If you have a Cartesian robot, see which motor connects to which stepper driver in the array above. If you use another type of arm solution, see the specific documentation.)

Steps per millimeter

A stepper motor driver operates in steps. It moves a certain number of steps in one direction, then a certain number of steps in another. You think in millimeters. You want your machine to go to a certain position in millimeters, then another position in millimeters.

You need Smoothieboard to convert the millimeters you ask of it, into steps the stepper motor driver understands.

That conversion depends on your exact arm solution. The most common, and the simplest, is the Cartesian arm solution, and it is the one we will focus on here. Documentation for other arm solutions can be found separately.

In the case of a Cartesian arm solution, you simply convert a certain number of millimeters to a certain number of steps. That is the

To compute it, you must multiply a certain number of factors.

- The object you move moves a certain number of millimeters for each rotation of the stepper motor. (This depends on the characteristics of the belt/pulley, or lead-screw system you are using.)

- The stepper motor moves a certain number of full steps per rotation. That is usually 200. (But it can be 400.)

- Each step is divided by the stepper motor driver into a certain number of microsteps. It is that number, and not the number of full steps, that we want. Smoothieboard V1.1 always divides steps into 32 microsteps. (16 for older smoothieboards).

The formula is as follows:

steps per millimeter = ((full steps per rotation) x (microsteps per step)) / (millimeters per rotation)

To help you, there is an awesome calculator by the awesome Josef Prusa: http://calculator.josefprusa.cz/

Once you know the correct value for a given stepper motor driver, set it in the config file.:

alpha_steps_per_mm 80 # Steps per mm for alpha stepper

[actuator]

alpha.steps_per_mm = 80 # Steps per mm for alpha stepper

Do this for each stepper motor driver.

In the case of your extruder stepper motor, the principle is the same, but the value is

Here is a good video on steps per millimeters:

Direction

It is now time to test your stepper motors. For this, you will need to use host software like Pronterface or the web interface.

Now connect to your Smoothieboard over the serial interface. Power your machine on by plugging the PSU into the wall.

Now you need to move an axis to make sure the stepper motor is turning in the right direction. In Pronterface, click near the yellow arrow marked “+X”.

Your X axis will move. If it moved to the right, great! Everything is fine, and you have nothing to change. If it moved to the left, you need to invert the direction of that axis.

You do this by editing the configuration file, and inverting the direction pin for that stepper motor driver:

alpha_dir_pin 0.5 # Pin for alpha stepper direction

Becomes:

alpha_dir_pin 0.5! # Pin for alpha stepper direction

[actuator]

alpha.dir_pin = 0.5 # Pin for alpha stepper direction

Becomes:

[actuator]

alpha.dir_pin = 0.5! # Pin for alpha stepper direction (inverted)

This is for your axes. In the case of your extruder, the config value is

Save the config file, reset the Smoothieboard, connect again using Pronterface. Now the axis will move in the right direction.

Do this for each axis.

If you have a moving bed in the Y axis for example, as opposed to a moving tool, be careful: what matters is the direction of the head relative to the bed, not the direction of the bed relative to the machine.

It's very common to get confused and invert your Y axis on moving bed machines (or not invert it when it should be).

Basically, if an asymmetrical object looks like the model when it is printed, then your Y axis is correct, otherwise you need to change your configuration.

Arm Solutions

On a typical “Cartesian” machine, each actuator (a motor and a linear rail, named alpha, beta, gamma) corresponds to an axis (like X, Y, and Z).

However, on other machines, the position in Cartesian space (X, Y, Z) must be converted, using math, into a more complex position for the actuators.

This is the case, for example, of linear delta (often just called “delta”) machines.

Supported Arm Solutions

Smoothieware supports multiple arm/motion solutions to accommodate different machine architectures. The table below shows which solutions are available in each firmware version:

| Setting | v1 | v2 | Description | Documentation |

|---|---|---|---|---|

| ✅ | ✅ | Standard X/Y/Z configuration where each motor directly controls one axis | Cartesian | |

| ✅ | ✅ | Three vertical linear rails in triangular configuration (Rostock, Kossel) | Delta | |

| ✅ | ✅ | Crossed-belt system where both motors contribute to X and Y movement | HBot/CoreXY | |

| ✅ | ✅ | Crossed-belt variant where both motors contribute to X and Z movement | CoreXZ | |

| ✅ | ✅ | SCARA-style robotic arm with two parallel rotary joints | Morgan SCARA | |

| ✅ | ✅ | Delta variant using rotating joints instead of linear slides (experimental) | Rotary Delta | |

| ✅ | ❌ | Cartesian system rotated by a specified angle (v1 only) | Rotatable Cartesian |

linear_delta,delta,rostock, orkosselall select Linear Deltahbotorcorexyboth select HBot (they use the same implementation)morganselects Morgan SCARA

Configuration

To configure your machine for the right type, see its specific page linked in the table above.

Each arm solution has its own configuration parameters and requirements. The

V1 Configuration (flat namespace):

arm_solution cartesian

For example, to configure a linear delta printer:

arm_solution linear_delta

V2 Configuration (INI sections):

[motion control]

arm_solution = cartesian

For example, to configure a linear delta printer:

[motion control]

arm_solution = linear_delta

If no arm solution is specified, cartesian is used by default.

Extruder

Extruders are used to push plastic filament through a hotend, to achieve the awesome feat of 3D Printing.

This module controls the motor that pushes the filament, it does not take care of the hotend itself, which is the job of TemperatureControl.

Steps Per Millimeter Configuration:

The most important parameter to get your extruder module to work properly is the steps per millimeter setting:

extruder.hotend.steps_per_mm 140

[extruder]

hotend.steps_per_mm = 140

You can create as many Extruder modules as you want (although you may run out of memory and Smoothie will no longer boot), as long as you give them different module names.

You can name those modules whatever you want (as long as you stick to only alphanumerical characters).

make AXIS=6.

Configuration

Steps per millimeter

We need to find the number of steps the stepper motor drivers have to generate in order to move the filament 1 millimeter.

This value depends on your stepper motor, the microstepping on your stepper motor drivers, the gear reduction ratio on the extruder assembly if any, and the diameter of your hobbed pulley/bolt.

A very good guide on how to find this value can be found here: Triffid Hunter’s Calibration Guide.

extruder.hotend.steps_per_mm 140

[extruder]

hotend.steps_per_mm = 140

Filament diameter

This is an optional parameter for those who want to use volumetric extrusion, but are too lazy to do their own math. ;)

Simply enter the machine’s filament diameter here and set your slicer’s filament diameter to 1.128379mm (2*sqrt(1/pi)) and enjoy portable gcode!

Further explanation can be found in Triffid Hunter’s guide, linked above.

Note that when firmware retraction is specified via {::nomarkdown}

In the current master builds, only print moves have E specified in mm³, retract or extrude only moves are still in mm. The change in edge is to be more compliant with other firmwares and user expectations.

extruder.hotend.filament_diameter 3.0

[extruder]

hotend.filament_diameter = 3.0

The filament diameter can also be saved at runtime with this M code:

| Set E units for volumetric extrusion - D |

and saved with

Firmware Retract

Note this is optional, you are not obligated to set this up, but it is a nice feature if you want to use it.

The amounts of extrusion and speed can be set with the following M codes:

| set retract length S[positive|mm] F[feedrate|mm/min] Z[additional|zlift/hop] Q[zlift|feedrate mm/min] | ||

| set retract recover length S[positive|mm surplus to the M207 S*] F[feedrate|mm/min] |

or can be set in config with the following settings:

extruder.hotend.retract_length 3 # retract length in mm

extruder.hotend.retract_feedrate 45 # retract feedrate in mm/sec

extruder.hotend.retract_recover_length 0 # additional length for recover

extruder.hotend.retract_recover_feedrate 8 # recover feedrate in mm/sec (should be less than retract feedrate)

extruder.hotend.retract_zlift_length 0 # zlift on retract in mm, 0 disables

extruder.hotend.retract_zlift_feedrate 6000 # zlift feedrate in mm/min (Note mm/min NOT mm/sec)

[extruder]

hotend.retract_length = 3 # retract length in mm

hotend.retract_feedrate = 45 # retract feedrate in mm/sec

hotend.retract_recover_length = 0 # additional length for recover

hotend.retract_recover_feedrate = 8 # recover feedrate in mm/sec (should be less than retract feedrate)

hotend.retract_zlift_length = 0 # zlift on retract in mm, 0 disables

hotend.retract_zlift_feedrate = 6000 # zlift feedrate in mm/min (Note mm/min NOT mm/sec)

These can be set differently for each extruder defined.

Pins

As all stepper motors, the extruder stepper motor needs 3 pins to be controlled: step, direction, and enable (See Pin Reference and Pinout):

1st Extruder (delta, or M4)

extruder.hotend.step_pin 2.3

extruder.hotend.dir_pin 0.22

extruder.hotend.en_pin 0.21

[extruder]

hotend.step_pin = PD3

hotend.dir_pin = PD4

hotend.en_pin = PD5

2nd Extruder (epsilon, or M5)

extruder.hotend2.step_pin 2.8

extruder.hotend2.dir_pin 2.13

extruder.hotend2.en_pin 4.29

You can make your extruder module use any other stepper motor driver, or even an external stepper motor driver, simply by providing the adequate pins for that driver, see Pinout.

Current

On boards which feature current control of the stepper motor drivers (Smoothieboard or 4pi), you have to set that value for the extruder too.

This is handled by the Currentcontrol module, but usually, the line for the configuration of a given stepper motor is written along with its pins, for clarity.

delta_current 1.5

[tmc2660]

delta.current = 1500 # Current in milliamps (mA), not Amps

[tmc2660] or [tmc2590] section depending on your driver type.

Set the value to the exact value your stepper motor is rated for (or less, for less noise, but less torque).

Setting the current to a value higher than the recommended one causes overheating, and skipped steps.

Example

Here is an example of a common configuration and wiring of an extruder with a Smoothieboard.

This example setup is of an extruder (stepper motor) connected to the M4 stepper motor driver.

If your machine has multiple extruders, you also want to look at multiple-extruders.

Configuration

The default Smoothie configuration example contains an example extruder section, this means you do not need to create a new one, but you can just re-use the sample one.

The configuration looks like this:

## Extruder module configuration

# See /extruder

extruder.hotend.enable true # Whether to activate the extruder module at all. All configuration is ignored if false

extruder.hotend.steps_per_mm 140 # Steps per mm for extruder stepper

extruder.hotend.acceleration 500 # Acceleration for the stepper motor mm/sec²

extruder.hotend.max_speed 50 # Maximum speed in mm/s

extruder.hotend.step_pin 2.3 # Pin for extruder step signal

extruder.hotend.dir_pin 0.22 # Pin for extruder dir signal (add '!' to reverse direction)

extruder.hotend.en_pin 0.21 # Pin for extruder enable signal

delta_current 1.5 # Current setting in Amperes for this motor driver

## Extruder module configuration

# See /extruder

[extruder]

hotend.enable = true # Whether to activate the extruder module at all

hotend.steps_per_mm = 140 # Steps per mm for extruder stepper

hotend.step_pin = PD3 # Pin for extruder step signal

hotend.dir_pin = PD4 # Pin for extruder dir signal (add '!' to reverse direction)

hotend.en_pin = PD5 # Pin for extruder enable signal

[actuator delta]

acceleration = 500 # Acceleration for the stepper motor mm/sec²

[motion control]

max_speed = 50 # Maximum speed in mm/s

[tmc2660]

delta.current = 1500 # Current setting in milliamps for this motor driver

Now that your extruder is configured, you can wire it:

Wiring

Wiring your extruder stepper motor is very similar to how you wire your X, Y, and Z stepper motors (see adequate documentation):

you just wire the 4 wires of the stepper motor, to the output connector of the M4 stepper motor driver.

A hotend contains a thermistor and a heating element in its heating block.

Temperature control

In a 3D printer, you heat thermoplastics.

There are two different parts in which you want to do that:

First, the hot-end heats the plastic to the point where it is liquid enough to go through the nozzle.

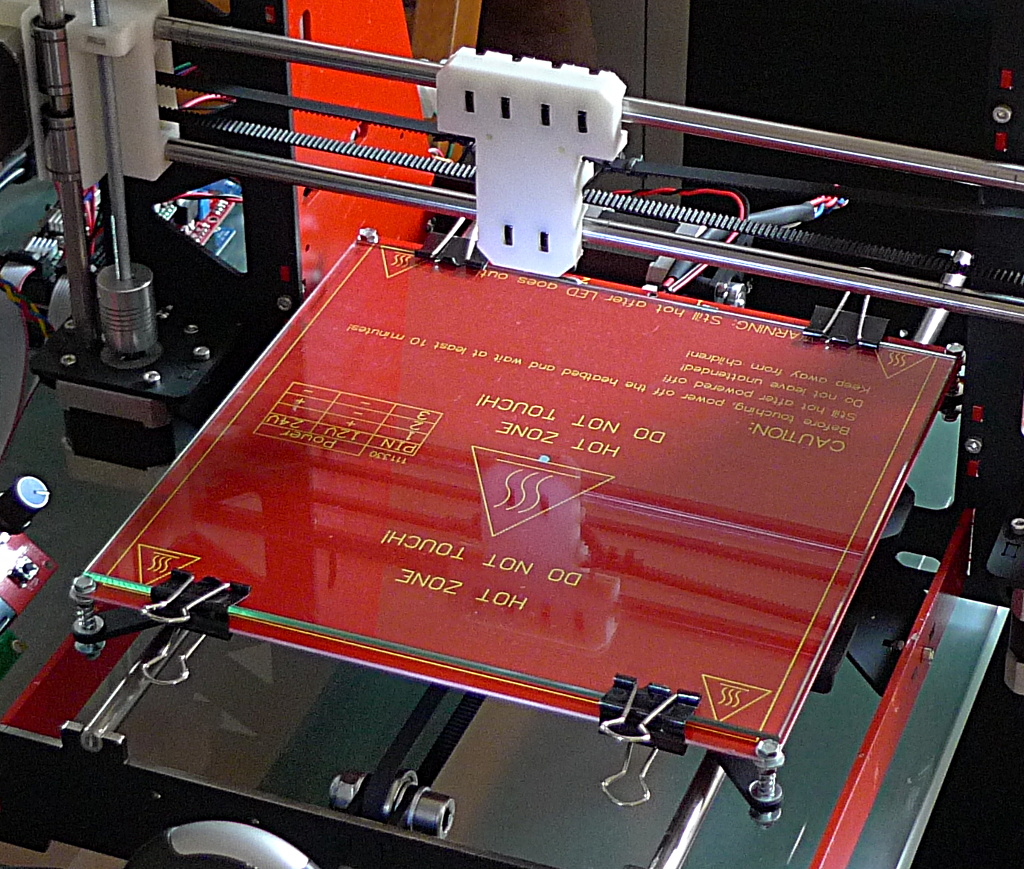

Second, the heated bed (in only some printers), on which the first layer is deposited, is heated to allow for better sticking of the plastic to the bed, and more uniform temperature in the part while printing.

For detailed information about temperature control in Smoothie, you can look at this part of the documentation: TemperatureControl

The process is essentially the same to wire and control a hot-end, or a heated bed, and is as follows:

Thermistor

A thermistor’s resistance changes with temperature.

By reading that resistance, we can determine the temperature of a hot-end or a heated bed.

This allows Smoothie to turn the heater on or off depending on the temperature it reads, to achieve the desired temperature.

There are 4 thermistor inputs, close to the SD card slot.

To wire the thermistor, take the two wires from the thermistor on your hot-end or heated bed, and connect them to one of the pairs of thermistor inputs on the Smoothieboard. Each input is two pins, one for each thermistor wire. There is no polarity to respect.

Smoothieboard has 4 thermistor inputs total, meaning a line of 8 pins on the edge of the board. Polarity is not important for thermistors.

When reading temperature, never use the normal ground to read temperatures, always use the AGND connections provided on the thermistor inputs.

This also means you cannot "share the ground" on wires going to your hotend, as some users sometimes do to "save wires". This is a very bad idea and will cause a lot of problems.

By convention (meaning that if you wire things according to the way it is specified in the default configuration file, you do not need to edit the configuration file as it will already be correct),

- Hot-end thermistor connects to T0

- Heated bed thermistor connects to T1

In the default configuration file, the thermistor pins are set up using that convention:

temperature_control.hotend.thermistor_pin 0.23 # Pin for the thermistor to read (here T0)

temperature_control.bed.thermistor_pin 0.24 # Pin for the heated bed to read (here T1)

You can, however, use any thermistor pin you want for any temperature control module you want.

Thermistors come in all shapes and sizes.

Thermistor Choice

Different models of thermistors are used in hotends or heated beds, and each type translates temperature into resistance differently. It’s essential to inform Smoothie about the specific thermistor model you have to ensure accurate temperature readings.

This configuration is done using the thermistor option in the configuration file. You provide the name of your thermistor, and Smoothie will handle the math accordingly.

V1 Configuration (flat namespace):

temperature_control.hotend.thermistor EPCOS100K

V2 Configuration (INI sections):

[temperature control]

hotend.thermistor = EPCOS100K

Currently, Smoothie recognizes the following thermistor models:

| Name | Beta for 0-80°C | Beta for 185-230°C | I for Steinhart Hart | J for Steinhart Hart | K for Steinhart Hart | Part number |

|---|---|---|---|---|---|---|

EPCOS100K |

4066 | 4193 | 0.000722378300319346F | 0.000216301852054578F | 9.2641025635702e-08F | B57540G0104F000 |

Honeywell100K |

3974 | 4385 | 0.000596153185928425F | 0.000231333192738335F | 6.19534004306738e-08F | 135-104LAG-J01 |

Semitec |

4267 | 4375 | 0.000811290160145459F | 0.000211355789144265F | 7.17614730463848e-08F | 104GT-2 |

Honeywell-QAD |

0.000827339299500986F | 0.000208786427208899F | 8.05595282332277e-08F | 135-104QAD-J01 | ||

Semitec-104NT4 |

0.000797110609710217F | 0.000213433144381270F | 6.5338987554e-08F | 104NT-4R025H42G | ||

RRRF100K |

3960 | |||||

RRRF10K |

3964 | |||||

HT100K |

3990 |

Unknown Thermistor

If your thermistor is not recognized by Smoothie, you can define the parameters manually in the configuration file using either the beta value or the Steinhart Hart algorithm.

Using Beta Values

Set the beta value in the configuration file:

V1 Configuration:

temperature_control.hotend.beta 4066 # set beta for thermistor

V2 Configuration:

[temperature control]

hotend.beta = 4066 # set beta for thermistor

This makes beta values generally suitable for heated beds but not for hotends.

If the thermistor is 100K ohms at 25°C, this setting is usually sufficient. Additional settings like r0, t0, r1, r2 are not typically needed as the defaults work well.

If you’re unsure about your thermistor model, contact the designer or seller of your 3D printer, hotend, or heated bed to obtain the specifications and beta value.

Using the Steinhart Hart Algorithm

This is the preferred method. Set the Steinhart Hart coefficients in the configuration file:

V1 Configuration:

temperature_control.hotend.coefficients 0.000722376862540841,0.000216302098124288,0.000000092640163984

V2 Configuration:

[temperature control]

hotend.coefficients = 0.000722376862540841,0.000216302098124288,0.000000092640163984

To determine the Steinhart Hart coefficients for your thermistor, please refer to the SteinhartHart page.

Alternatively, if you have the temperature curve for your thermistor, you can define three points on that curve and let Smoothie calculate the coefficients:

V1 Configuration:

temperature_control.hotend.rt_curve 20.0,126800,150,1360,240,206.5

V2 Configuration:

[temperature control]

hotend.rt_curve = 20.0,126800,150,1360,240,206.5

Heating element

Now that Smoothie can read the temperature, it needs a way to heat things and maintain a desired temperature.

This is the heating element.

On a hot-end, that is usually a resistor or a cartridge heater, on a heated bed, that is usually a PCB plate designed to have the right resistance, or a kapton heated bed.

Because of its resistance, when power is applied to a heater, the heater consumes energy to generate heat.

These heating elements need to be connected to Smoothieboard on a port that allows Smoothie to turn them ON or OFF as needed. This is done by the use of MOSFET that takes a digital input signal, and, depending on its value, lets current pass or not.

MOSFETs

Smoothie has up to 6 MOSFET controls (6 on 5X, 4 on 4X, and 2 on 3X).

The MOSFETs act as switches to ground: loads must be connected between the power source and the MOSFET switched terminal.

When the MOSFET is switched on, power will be applied to the load.

When the MOSFET is switched off, power will be removed, because one load terminal will be essentially disconnected and current cannot flow.

The exception being inductive load ‘flyback’ switching transients, discussed above.

Connect your PSU to the power input connector for those FETs (providing power to the load), and connect your power-consuming element (be it heating element, spindle, etc.) between the power output terminal and the MOSFET terminal.

Smoothie connects/disconnects the element’s ground as needed to maintain temperature or as requested by G-codes.

There are three main pairs of MOSFETs on the board:

MOSFET Overview

Smoothieboard v2 has a simplified and safer MOSFET architecture compared to v1:

| Output Type | Count | Current | Purpose |

|---|---|---|---|

| Low-Current FETs | 4 | ~5A each | Hotend1, Hotend2, Fan1, Fan2 |

| Bed FET | 1 (2× parallel) | ~10-12A | Heated bed |

| SSR Outputs | 2 | Milliamps | Solid-state relay control |

All MOSFET outputs are powered from the VFET power input (2× XT30 connectors, 30A total).

Key Safety Feature: High-Side PFET Watchdog

The 4 low-current FETs share a common +VFET rail controlled by a high-side P-channel MOSFET (PFET) watchdog. The firmware can instantly kill power to all 4 outputs if a thermal runaway or fault is detected.

How it works:

- All 4 low-current FETs (hotends, fans) connect to a shared +VFET power rail

- This rail is controlled by a high-side PFET watchdog

- If any low-side FET fails shorted (stuck ON), the high-side PFET can still disconnect power

- Provides an additional layer of protection against thermal runaway

Bed FET Independence:

- The heated bed FET is NOT controlled by the high-side PFET watchdog

- This is deliberate: allows the bed to remain on even if other FETs are shut down

- Bed thermal runaway protection is handled directly by firmware

Low-Current FETs (Hotends, Fans)

| Specification | Value |

|---|---|

| Outputs | 4 (hotend1, hotend2, fan1, fan2) |

| Current Rating | ~5A per output |

| Voltage | Up to 24V |

| Power Source | Shared +VFET rail |

| Safety | High-side PFET watchdog |

| Control | PWM capable (firmware-controlled frequency) |

| LED Indicators | Yes (per output) |

Bed FET

| Specification | Value |

|---|---|

| Configuration | 2× MOSFETs in parallel |

| Combined Current | ~10-12A |

| Voltage | Up to 24V |

| Power Source | Direct from VFET (not through PFET watchdog) |

| Control | PWM capable |

| LED Indicator | Yes |

200W bed @ 12V: 16.7A - Consider using an external SSR

200W bed @ 24V: 8.3A - Within bed FET capacity

SSR Outputs

| Specification | Value |

|---|---|

| Outputs | SSR1, SSR2 |

| Type | Logic-level (3.3V or 5V signal) |

| Current | Milliamps (for SSR coil drive) |

| Use Cases | Solid-state relay control, auxiliary outputs |

Use SSR outputs to control external solid-state relays for:

- High-power heated beds (>12A)

- AC-powered heaters

- Other high-current loads

Power LED Indicators

Each MOSFET output has its own LED indicator showing when it’s active:

- Hotend1 LED: Hotend 1 heater active

- Hotend2 LED: Hotend 2 heater active

- Fan1 LED: Fan 1 active

- Fan2 LED: Fan 2 active

- Bed LED: Heated bed active

-

Big MOSFET pair: Their outputs are labeled P

2.7 and P2.5 on the schematic, the input connector for them is found between them. They are found on the 4X and 5X boards. To power those MOSFETs, you need to provide them with power by wiring their power input to the power supply. -

Small MOSFET pair: Their outputs are labeled P

2.6 and P2.4 on the schematic, the input connector for them is found by their side, between P2.6 and P1.23 . They are found on all of the boards. To power those MOSFETs, you need to provide them with power by wiring their power input to the power supply. -

Mixed MOSFET pair: Their outputs are labeled P

1.22 and P1.23 on the schematic. The pair is called “mixed” because it consists of one big MOSFET and one small MOSFET. They do not have a specific input, they take power directly from VBB (the Stepper motors power input described in the Stepper Motors chapter). To power those MOSFETs, you need to provide them with power by wiring their power input (which is the same as the one for the stepper motors) to the power supply.

This allows you to use different voltages for different things if you want, and makes it easier to use more current as the current is shared between more connectors. It does mean wiring one or two more connectors though.

If you are trying to control MOSFETs and they are not turning on, make sure you provided power to their power input.

MOSFETs list:

| MOSFET group | MOSFET name | Controlling pin | Output connector | Input method | Voltage | Current |

|---|---|---|---|---|---|---|

| Big MOSFETs | First big MOSFET | X15 | Big MOSFETs power input X13 | 12-24V | 12.5A max | |

| Big MOSFETs | Second big MOSFET | X10 | Big MOSFETs power input X13 | 12-24V | 12.5A max | |

| Small MOSFETs | First small MOSFET | X7 | Small MOSFETs power input X6 | 12-24V | 3A max | |

| Small MOSFETs | Second small MOSFET | X8 | Small MOSFETs power input X6 | 12-24V | 3A max | |

| Mixed MOSFETs | Third big MOSFET | X16 | VBB (motor) input | 12-24V | 12.5A max | |

| Mixed MOSFETs | Third small MOSFET | X9 | VBB (motor) input | 12-24V | 3A max |

MOSFETs diagram

+ on that connector to + on your PSU, and - to - on the PSU.

Heater elements, however, do not have a polarity, so you do not have to worry about polarity on the outputs.

If you are using another output element like a Peltier or a Spindle, you need to be careful to respect the polarity for the outputs too.

Never use the big MOSFETS for more than 12.5A (and monitor connector and MOSFET temperatures at that current use, too much heating can be a sign of a bad wire connection), and the small MOSFETS should never be used for more than 3A.

Trying to power a 40W (or more) hotend cartridge heater at 12V with the small FETs will destroy them, usually locking (melting) them to the “ON” state (shorted) and possibly destroying the circuitry driving the MOSFET gate.

If you need to control more than 12 Amps, you cannot do it with one of the MOSFETS on board, however, you can use a Solid State Relay.

For information see the Solid State Relay Appendix on this page.

There is an alternative, however (for currents up to 2 Amps or 4 Amps). For each pair, you can use jumpers (one jumper for the small MOSFETS pair (JP28), two parallel jumpers for the two big MOSFETS pair (JP11 and JP27)).

If you solder the pins for those OR connect a jumper to those pins, closing the circuit to VBB (the stepper motors power input), allowing you to take the power from those MOSFETS from the same place as the stepper motors do.

In the case of the big MOSFETS, you have to solder and put in place two jumpers, in parallel, in order to handle more current.

This means you cannot use this way of powering your MOSFETS if you are going to use more than 2A (for the small MOSFETS) or 4A (for the big MOSFETS, with both jumpers used, for 2 x 2A).

Do not use the jumpers to power a heated bed, for example, as it uses much more than 4A.

Wiring MOSFET Outputs

Power Connection

All MOSFET outputs on Smoothieboard v2 are powered from the VFET power input:

Unlike v1, Smoothieboard v2 has a single VFET power input (2× XT30 connectors) that powers ALL MOSFET outputs. No separate power inputs for different MOSFET groups!

Wiring steps:

- Connect your 12-24V power supply to the VFET XT30 connectors

- Connect your heaters/fans between the MOSFET output terminals and ground

- That’s it - no jumpers or multiple power connections needed!

MOSFET Output List

| Output | Type | Current | Typical Use |

|---|---|---|---|

| Hotend1 | Low-current FET | ~5A | First hotend heater |

| Hotend2 | Low-current FET | ~5A | Second hotend heater |

| Fan1 | Low-current FET | ~5A | Part cooling fan |

| Fan2 | Low-current FET | ~5A | Auxiliary fan |

| Bed | Dual parallel FETs | ~10-12A | Heated bed |

| SSR1 | Logic output | mA | External SSR control |

| SSR2 | Logic output | mA | External SSR control |

Polarity and Safety

+ on your PSU to the + terminal on the XT30 connectors.

Heater elements (resistive) do not have a polarity, so you do not have to worry about polarity on the outputs.

If you are using a Peltier element or a DC motor, you need to respect the polarity for the outputs.

High-Current Loads (>12A)

If you need to control more than 10-12A (the bed FET limit), use the SSR outputs to control an external Solid State Relay:

- SSR1/SSR2 provide logic-level signals to drive SSR coils

- Use a properly rated SSR for your load (e.g., 40A SSR for AC-powered heated beds)

- SSRs are recommended for AC mains-powered heaters

For information see the Solid State Relay Appendix.

Heated beds are often made out of a rigid, or flexible (kapton) PCB.

Example

Let’s say you want to connect a heated bed to your Smoothieboard.

First, wire the thermistor to the thermistor input.

Then, find out (from the Internet, or your seller/manufacturer) the current rating for that heated bed.

In this example it will be the classical RepRap PCB plate Heatbed.

Ours has an 11A current rating, this means we cannot use it with a small MOSFET, and we need to wire it to a big MOSFET.

We connect our PSU to the power input for the big MOSFETS pair (don’t forget to check the labels on the board for polarity).

Then we connect the two wires from the PCB bed to one of the big MOSFETS out. Polarity is not important here.

Because this is the heated bed, we connect it to the P2_7 (pin

For the hot-end, the default output is P2_4 (pin

To set a different MOSFET output for the bed or the hot-end, you have to edit the configuration file to the digital output pin corresponding to your chosen MOSFET. These are the lines you would have to edit:

temperature_control.hotend.heater_pin 2.7 # Pin that controls the heater cartridge for the hot-end

temperature_control.bed.heater_pin 2.5 # Pin that controls the heated bed

To help you figure out what is what, here is a recapitulating table:

MOSFETs Table

This page documents the MOSFET outputs available on Smoothieboard and their specifications.

MOSFETs are used to control high-power devices like heated beds, hotends, fans, and other accessories.

MOSFET Specifications

| MOSFET Pair | Big MOSFETS | Small MOSFETS | Mixed MOSFETS | |||

|---|---|---|---|---|---|---|

| Label on diagram | P |

P |

P |

P |

P |

P |

| Digital output pin | ||||||

| Power Input | Between P |

Between P |

Taken from VBB | |||

| Size | Big | Big | Small | Small | Big | Small |

| Maximum current | 12A | 12A | 3A | 3A | 12A | 3A |

| Used by default for | Heated bed | Hotend 0 | Fan | Hotend 1 |

Understanding MOSFET Pairs

Smoothieboard has three MOSFET pairs:

Big MOSFETs Pair (P2.7 and P2.5 )

- Current capacity: 12A each

- Power input: Shared between the two outputs (between P

2.7 and P2.5 terminals) - Typical use: Heated bed (high current devices)

- Note: Both outputs share the same power input

Small MOSFETs Pair (P2.4 and P2.6 )

- Current capacity: 3A each

- Power input: Shared between the two outputs (between P

2.6 and P1.23 terminals) - Typical use: Hotend 0 and fan (moderate current devices)

- Note: Both outputs share the same power input

Mixed MOSFETs Pair (P1.23 and P1.22 )

- Current capacity: P

1.23 : 12A, P1.22 : 3A - Power input: Taken directly from VBB (main power supply)

- Typical use: P

1.23 for Hotend 1, P1.22 for accessories - Note: These outputs use the main VBB power supply

| Output | Controlling Pin | Current Rating | Typical Use |

|---|---|---|---|

| Hotend A | ~5A | Primary hotend heater | |

| Hotend B | ~5A | Secondary hotend heater | |

| Fan 1 | ~5A | Part cooling fan | |

| Fan 2 | ~5A | Auxiliary fan | |

| Bed | ~10-12A | Heated bed (dual parallel FETs) | |

| SSR1 | Logic output | mA | External SSR control |

| SSR2 | Logic output | mA | External SSR control |

Understanding MOSFET Outputs

Smoothieboard v2 has a simplified MOSFET architecture:

Low-Current FETs (Hotend A, Hotend B, Fan 1, Fan 2)

- Current capacity: ~5A each

- Power input: Shared VFET rail (2× XT30 connectors)

- Safety feature: High-side PFET watchdog can cut power to all 4 outputs

- Note: All share the same power source, controlled by safety watchdog

Bed FET

- Current capacity: ~10-12A (dual parallel MOSFETs)

- Power input: Direct from VFET (not through PFET watchdog)

- Typical use: Heated bed

- Note: Independent of safety watchdog for bed stability

SSR Outputs

- Current capacity: Milliamps (logic level signals)

- Use: Control external solid-state relays for high-power loads

Important Safety Notes

Configuration

To configure a MOSFET output in your config file, use the appropriate pin number from the “Digital output pin” row.

Example for configuring a heated bed on P

temperature_control.bed.heater_pin 2.7

Example for configuring a hotend on P

temperature_control.hotend.heater_pin 2.4

Example for configuring a heated bed on P

[temperature_control.bed]

heater_pin = 2.7

Example for configuring a hotend on P

[temperature_control.hotend]

heater_pin = 2.4

Related Documentation

- Smoothieboard - Main board documentation

- Temperature Control - Configuring heaters

- Pinout - Complete pinout diagram

- How to Wire - Wiring tutorials and best practices

Testing

Once your thermistor is connected, and both the power input and the heater elements are plugged in, you are ready to test your temperature controller.

To do this, reset your Smoothieboard, then connect to it using host software like Pronterface, or using the web interface.

Now connect to your Smoothieboard over the serial interface.

Power your machine on by plugging the PSU into the wall.

If anything burns or smells funny, turn everything off immediately and investigate.

The heaters are off by default when Smoothie starts. Check that they are not heating (one indication of the heater being ON is if the LED near the MOSFET is lit up, the other being checking the heater itself), if they are heating, something is wrong, turn everything off immediately and investigate.

Now, in Pronterface, set the temperature for either your bed or your hot-end, depending on what you are testing (wire and test only one at a time for easier problem investigation) at a low temperature (20°C above room temperature is a good idea), and monitor temperature to see if the temperature rises. If it does rise, everything is fine. If not, turn everything off immediately and investigate.

Once you know the heater works correctly, there is still some tuning to do: tuning your PID settings.

PID

Temperature Control PID

Why PID is Important

PID is crucial for stable temperature control.

Without PID, a simple way to control temperature would be:

- If temperature too cold, turn heater on

- If temperature too hot, turn heater off

But there is a big problem with that method.

Due to temperature not traveling instantly from the heater to the thermistor, when the thermistor reads a given temperature, the heater is already hotter than what the thermistor reads.

This overshooting is something we do not want.

It means reaching temperatures that could be undesirable, and it means you will not be able to correctly stabilize the temperature.

What is PID?

The solution to this is PID.

It uses some math, allowing us to correct those problems by turning the heater on and off in a smarter sequence.

PID stands for:

- Proportional - Responds to current error

- Integral - Responds to accumulated error over time

- Derivative - Responds to rate of change of error

Configuring PID Values