Basics

The Spindle is the main effector on your CNC Mill/Router.

It holds the end mill or drill bit, makes it turn and remove material.

While manual control is sometimes fine (turn it on before starting your G-code, off when you are done), it is so much neater to have G-codes to control it automatically.

Simply put an ON G-code at the beginning of your G-code file, and an off G-code at the end of your G-code file, and you don’t have to think about it anymore.

The spindle module supports different types of spindles which are described in the following subsections.

General

The spindle module has an option which lets you enable or disable the entire module:

V1 Configuration (flat namespace):

spindle.enable true # set this to false to disable the spindle module

spindle.ignore_on_halt false # set to false to turn off spindle during HALT (safe, recommended)

# set to true to keep spindle running during emergency stop/limit hit (use with extreme caution)

V2 Configuration (INI sections):

[spindle]

enable = true # set this to false to disable the spindle module

ignore_on_halt = false # set to false to turn off spindle during HALT (safe, recommended)

# set to true to keep spindle running during emergency stop/limit hit (use with extreme caution)

G-code

Available G-code commands:

M3 will start the spindle.M3 S5000 will start the spindle and set speed to 5000 RPM.M5 will stop the spindle. Last set RPM is remembered and used for nextM3 command ifS argument is not given.M957 will report the current spindle speed and PWM value. This returns not the actual value but the value that was set throughM3 .M958 will report the current PID parameters.M958 Px.xxx Ix.xxx Dx.xxx will set them (to save the new values, you need to edit config file manually).

PWM Spindle

It needs a feedback sensor to adjust the speed using a PID control.

Example config options

V1 Configuration (flat namespace):

spindle.type pwm # sets the spindle module to PWM mode

spindle.pwm_pin 2.5 # Big Mosfet Q7. Pin must be hardware PWM capable.

spindle.pwm_period 1000 # default 1000, sets the PWM frequency

spindle.max_pwm 1.0 # maximum PWM duty cycle (0.0 to 1.0)

# limits power to protect motor from overcurrent

# set lower if motor runs too hot at full power

spindle.feedback_pin 2.7 # Pin must be interrupt capable.

spindle.pulses_per_rev 1.0 # default 1. Defines the number of pulses occur for each rotation

spindle.default_rpm 5000 # default 5000. Defines a default RPM value in case no RPM value is provided.

spindle.control_P 0.1 # default 0.0001. P value for the PID controller

spindle.control_I 0.1 # default 0.0001. I value for the PID controller

spindle.control_D 0.1 # default 0.0001. D value for the PID controller

spindle.control_smoothing 0.1 # default 0.1. This value is low pass filter time constant in seconds.

V2 Configuration (INI sections):

[spindle]

type = pwm # sets the spindle module to PWM mode

pwm_pin = 2.5 # Big Mosfet Q7. Pin must be hardware PWM capable.

pwm_period = 1000 # default 1000, sets the PWM frequency

max_pwm = 1.0 # maximum PWM duty cycle (0.0 to 1.0)

# limits power to protect motor from overcurrent

# set lower if motor runs too hot at full power

feedback_pin = 2.7 # Pin must be interrupt capable.

pulses_per_rev = 1.0 # default 1. Defines the number of pulses occur for each rotation

default_rpm = 5000 # default 5000. Defines a default RPM value in case no RPM value is provided.

control_P = 0.1 # default 0.0001. P value for the PID controller

control_I = 0.1 # default 0.0001. I value for the PID controller

control_D = 0.1 # default 0.0001. D value for the PID controller

control_smoothing = 0.1 # default 0.1. This value is low pass filter time constant in seconds.

Since I'm experimenting with hobby ESC+motor combos (1:8 scale 3 phase 4068 like motor) I wanted to share its config.

ESCs act like hobby servos - 20 ms period time, 1.5-2ms duty cycle time - so instead of having modified the spindle code, I've created a switch for commands

Due to the very small duty cycle window, you won't have much control over the motor: S7.5 is neutral, S12.5 is "fastest" after calibrating the ESC manually with bCNC (read ESC's manual; below S7.5 is braking for now).

The following code is working, setting neutral upon boot - ESC init:

V1 Configuration (flat namespace):

switch.servo.enable true

switch.servo.input_on_command M3

switch.servo.input_off_command M5

switch.servo.output_pin 1.23o!

switch.servo.output_type hwpwm

switch.servo.startup_state true

switch.servo.startup_value 7.5

switch.servo.default_on_value 7.5

switch.servo.failsafe_set_to 0

V2 Configuration (INI sections):

[switch]

servo.enable = true

servo.input_on_command = M3

servo.input_off_command = M5

servo.output_pin = 1.23o!

servo.output_type = hwpwm

servo.startup_state = true

servo.startup_value = 7.5

servo.default_on_value = 7.5

servo.failsafe_set_to = 0

Analog Spindle

This module is used to control a VFD with a PWM that is converted to a 0-10V analog signal by an additional circuit.

That circuit also provides an optocoupler for switching the VFD RUN signal.

It is also the mode of choice if you run a brushless motor spindle driven by an ESC, in that case, you will not need any additional circuitry.

The downside is that the signal is not completely linear and may be interfered with by noise.

If you can use a VFD that supports Modbus/RS485, it's highly recommended to use that technique!

Example config options

V1 Configuration (flat namespace):

spindle.type analog # set the spindle type to analog, can also be used for ESC spindles controlled by a PWM

spindle.max_rpm 24000 # set the max spindle speed that is achieved at 100% PWM

spindle.min_rpm 100 # minimum spindle speed in RPM

# prevents unstable low-speed operation

# RPM below this (but > 0) are clamped to min_rpm

# M5 or S0 still turns spindle completely off

spindle.pwm_pin 2.4 # the pin which emits the PWM signal

spindle.pwm_period 1000 # the PWM frequency

spindle.switch_on_pin 2.6 # the pin which is used to enable the VFD (optional)

V2 Configuration (INI sections):

[spindle]

type = analog # set the spindle type to analog, can also be used for ESC spindles controlled by a PWM

max_rpm = 24000 # set the max spindle speed that is achieved at 100% PWM

min_rpm = 100 # minimum spindle speed in RPM

# prevents unstable low-speed operation

# RPM below this (but > 0) are clamped to min_rpm

# M5 or S0 still turns spindle completely off

pwm_pin = 2.4 # the pin which emits the PWM signal

pwm_period = 1000 # the PWM frequency

switch_on_pin = 2.6 # the pin which is used to enable the VFD (optional)

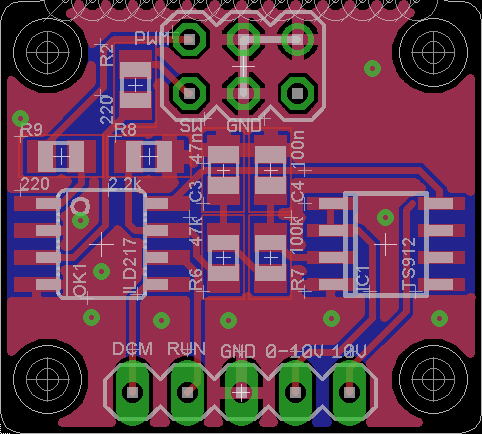

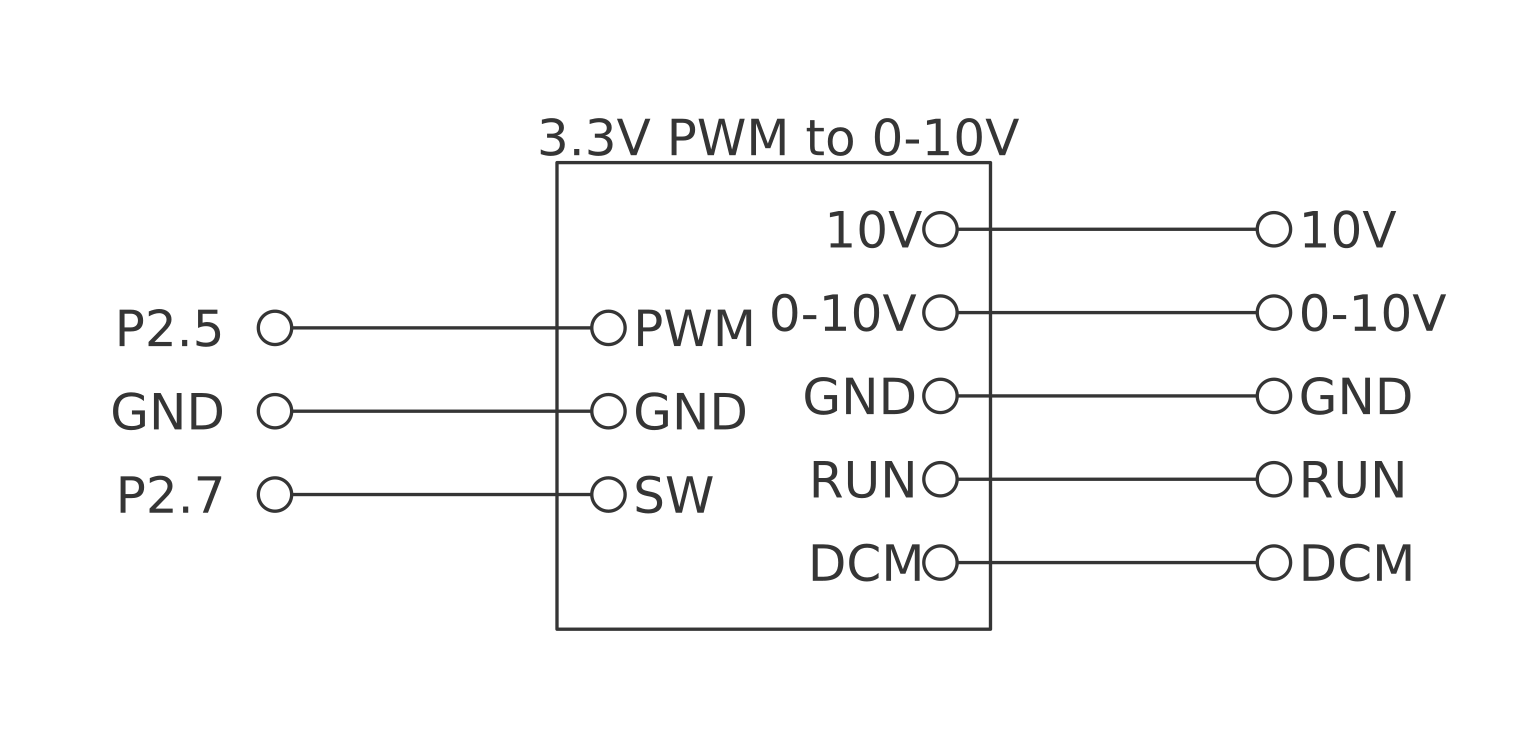

PWM to analog converter circuit

This is an example of a small extension PCB that contains a circuit to convert the 3.3V PWM signal into a 0-10V analog signal.

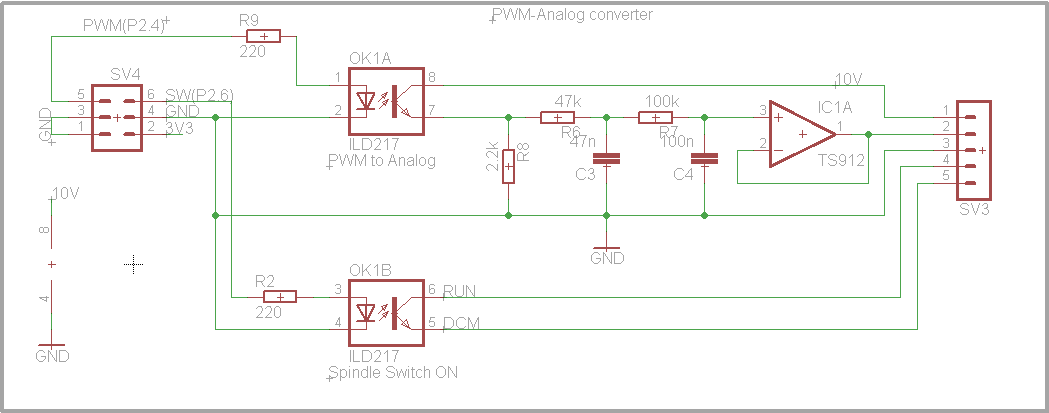

This is the related circuit diagram for the converter.

This example shows how to wire the Smoothieboard to a Huanyang VFD using the PCB shown above.

As you can see in the graph, the signal is better at the beginning and at the end.

Modbus Spindle

This module is used to control a VFD using an RS485 communication bus.

It provides a Modbus implementation and is easily extendable to support a wide range of Modbus compliant VFDs.

But it also can support VFDs that are not compliant with the Modbus standard such as the widely used Huanyang VFD that is popular and cheap on eBay.

At the time of writing only the Huanyang is implemented, but it is very easy to extend the module for many other models.

Example config options

V1 Configuration (flat namespace):

spindle.type modbus # set the spindle type to modbus/RS485

spindle.vfd_type huanyang # set the VFD type, this is necessary because each inverter uses its own commands

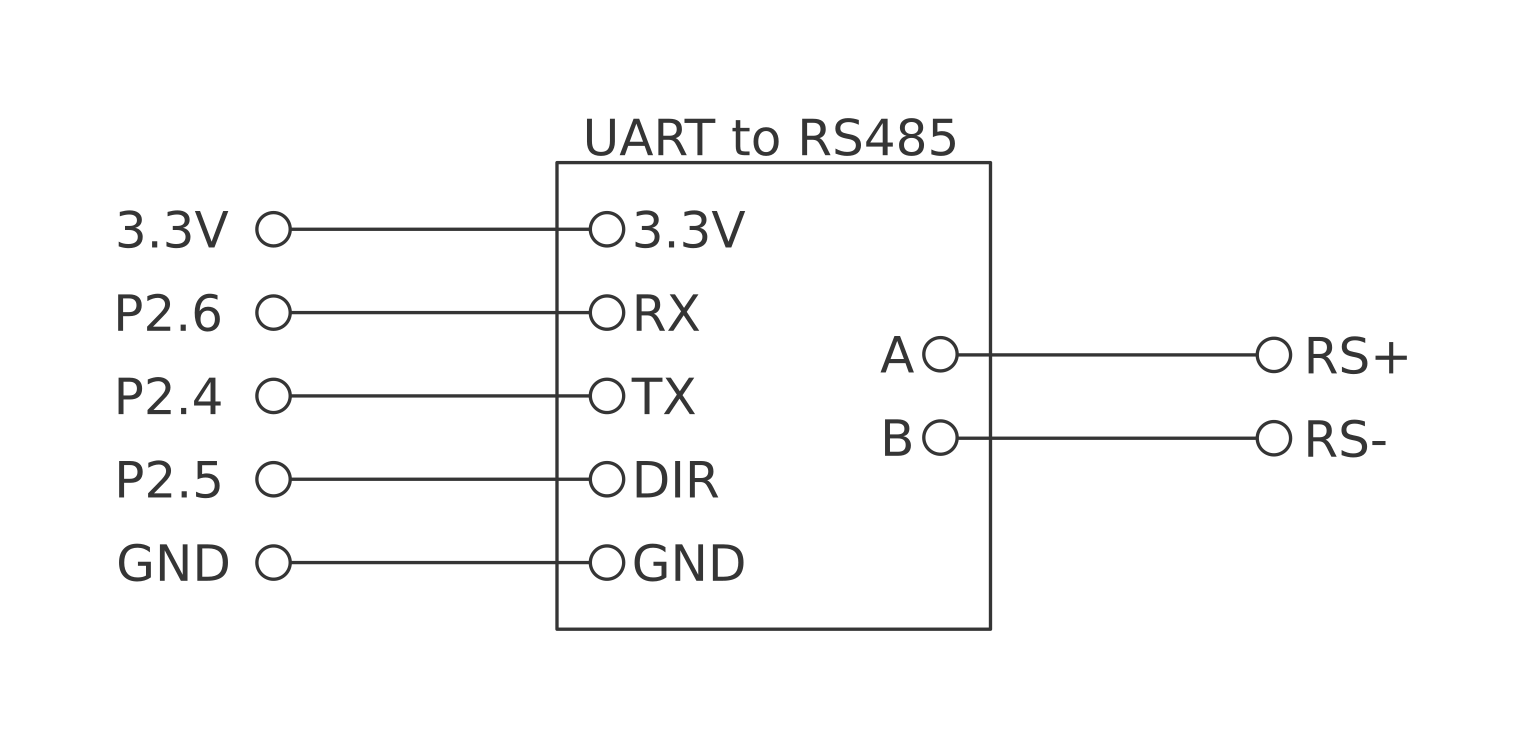

spindle.rx_pin 2.6 # RX pin for the soft serial

spindle.tx_pin 2.4 # TX pin for the soft serial

spindle.dir_pin 2.5 # RS485 is only half-duplex, so we need a pin to switch between sending and receiving

V2 Configuration (INI sections):

[spindle]

type = modbus # set the spindle type to modbus/RS485

vfd_type = huanyang # set the VFD type, this is necessary because each inverter uses its own commands

rx_pin = 2.6 # RX pin for the soft serial

tx_pin = 2.4 # TX pin for the soft serial

dir_pin = 2.5 # RS485 is only half-duplex, so we need a pin to switch between sending and receiving

Huanyang VFD Modbus Parameters

In order to get the Huanyang VFD accepting commands via ModBus, you need to change a few parameters:

- PD001: 2 (Source of run commands: communication port)

- PD002: 2 (Source of operating frequency: communication port)

- PD163: 1 (Communication address: 1)

- PD164: 1 (Communication Baud Rate: 9600)

- PD165: 3 (Communication Data Method: 8N1 RTU)

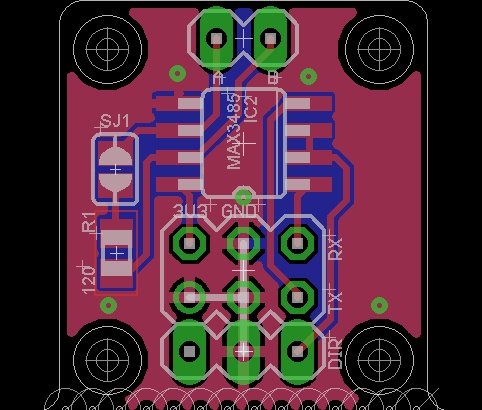

RS485 extension board

Like an analog spindle, the Modbus spindle needs an external circuit, but that is much simpler.

This is an example of a small extension PCB that contains a circuit to convert the 3.3V UART signal into an RS485 signal.

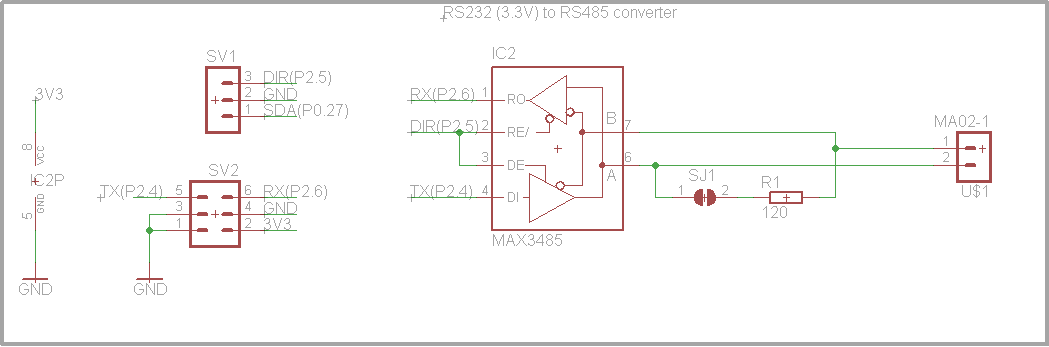

This is the related circuit diagram for the converter.

This example shows how to wire the Smoothieboard to a Huanyang VFD using the PCB shown above.