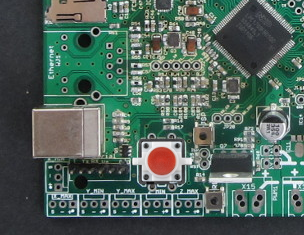

Smoothie Kill Button

There are two solutions for implementing a kill button on the Smoothieboard:

LED Tactile Button

Solder an LED Tactile Button on the Smoothieboard.

Simple Button

Wire a simple button on two pins.

The button may be configured as a kill switch, which will halt all operations, turn off heaters, and pause the host. It can be cleared with a

kill_button_enable true # set to true to enable a kill button

kill_button_pin 2.12 # kill button pin. default is same as pause button 2.12 (Add ^ for external buttons)

[kill button]

enable = true # set to true to enable a kill button

pin = 2.12 # kill button pin (Add ^ for external buttons)

When in the halted state (after the kill button is pressed), the play LED will flash rapidly. The kill state can be cleared by holding down the kill button for 2 seconds or more.

Alternatively, a latching E-Stop button can be hooked up to the kill button header (usually normally open). Then use this config:

kill_button_toggle_enable true # allows for latching estop button

[kill button]

toggle_enable = true # allows for latching estop button

When the E-Stop button is hit and latched on, it will halt the system. When it is unlatched and released, the system will exit the halt condition.

If you do not want the halt to exit when it is released, then set this:

unkill_enable false # do not unkill when button held or released

[kill button]

unkill_enable = false # do not unkill when button held or released

Stopping Smoothie

There are several different ways to stop Smoothie during operation, each with different behaviors and use cases.

Understanding these methods is important for safe operation and troubleshooting.

Stop Methods Comparison

| Command | G-code | Movement | Heaters | File playing | Recoverable | Documentation |

|---|---|---|---|---|---|---|

| abort | Stops SDCARD print immediately | Not affected | Aborts | Position maintained, file must be restarted | Player | |

| suspend | Stops once queue is empty | Turned off (if option enabled) | Paused, can be resumed | Yes, with resume or |

Player | |

| Kill button | Stops instantly (if button), waits for buffer (if host) | Turned off | Aborted | No, position lost, home required | supported-g-codes | |

| Control-X | - | Stops instantly, works during streaming | Turned off | Aborted | No, position lost, home required | - |

Detailed Method Descriptions

Abort Command (abort / M26)

Stops the execution of a file being played from SDCARD.

Behavior:

- Completes the current G-code

- Stops immediately after that

- Discards the rest of the queued commands

- Attempts to maintain the correct position after the abort

- Heaters remain at their current state

Use Case: Quick stop of a print job while preserving position and keeping heaters on.

Recovery: Position is maintained, but the file must be restarted from the beginning.

Documentation: Player module

Suspend Command (suspend / M600)

Suspends the execution of a file being played from SDCARD or being streamed from a host.

Behavior:

- Stops once the movement queue is empty

- All state is saved

- Heaters turned off by default (configurable)

- Jogging and extruding are allowed during suspension

- Can be resumed with resume or

M601

Use Case: Mid-print filament change or filament out detection.

Host Support: Requires upstream support. Currently Pronterface and OctoPrint support it. Other hosts need to be manually paused.

Recovery: Yes, fully recoverable with position maintained.

Documentation: Player module

Kill Button / M112

Emergency stop that instantly halts all operations.

Behavior:

- If kill button pressed: Stops instantly

- If

M112issued from host: Has to wait for the receive buffer to have room - All heaters turned off

- File playing aborted

- Position is lost

- System enters Halt state until

M999is sent

Use Case: Emergency situations requiring immediate stop.

Recovery: No, position is lost. Homing will be required.

Documentation: Supported G-codes, Kill Button

Control-X

Sends a control character to stop Smoothie instantly.

Behavior:

- Works at any time, even when streaming

- Same effect as the kill button

- All heaters turned off

- File playing aborted

- Position is lost

- System enters Halt state until

M999or$Xis sent

Use Case: Emergency stop from terminal/console when streaming G-code.

Recovery: No, position is lost. Homing will be required.

Halt State

When the kill button is pressed (or there is a temperature fault, M112 is issued, a limit switch is hit, or other error), the system enters the Halt state.

Halt State Behavior

- Play LED flashes

- Any command issued from host gets a

!!response (with a few exceptions) - PSU may be turned off if a PSU Switch is defined

Clearing Halt State

The Halt state can be cleared by:

- Issuing

M999from the host - Holding the flashing kill button for 2 seconds

- Using the LCD panel (if equipped)

Using Buttons and Sensors

Best Practices

For Normal Operation

- Use suspend/resume (

M600/M601) for planned interruptions like filament changes - Use abort when you need to stop quickly but keep heaters on

For Emergencies

- Use the kill button or Control-X for immediate emergency stops

- Remember that position will be lost and homing will be required

Recovery After Emergency Stop

- Clear the Halt state with

M999 - Home all axes before attempting further movement

- Check that heaters are at safe temperatures before proceeding

- Verify machine state before resuming work

Further Reading

- Player module documentation

- Kill Button setup

- Switch module - For configuring buttons and sensors

- Supported G-codes

- Power Supply Control - PSU shutdown on halt