Your guide to installing Smoothieboard in a Blue Box Laser Cutting machine

( See also blue-box-guide )

« Blue Box » laser cutters ( sometimes also referred to as K40 ) are cheap Chinese machines basically designed for laser engraving of stamps.

The electronics and software that come with it are generally considered barely usable, and are at the very least very limited.

However, the machine itself, while cutting cost at all corners, and not being of the best quality, is a good option ( and the cheapest option possible ) for anybody looking at getting started with laser cutting.

These machines can be found for $700 or even sometimes less on eBay, and have become more and more popular as people have started replacing the internal electronics, first with Arduino-based boards, and now with Smoothieboard. This allows for easier use, more software options, and makes for an overall much better machine.

Their work area is roughly A4 size, and the laser power is about 40W.

This allows the machine to cut and engrave plywood, MDF, balsa, cardboard, paper, leather, cloth, and PMMA ( acrylic ), up to about 5mm thickness.

This is a step-by-step guide to connecting your board to the various components of the laser cutter, configuring everything, from the beginning to actually cutting material.

This guide is a community effort, and this page is a Wiki. Please don’t hesitate to edit it to fix mistakes and add information, any help is very welcome.

About this guide

This guide is specific to the « Blue box » model that is very commonly found, but the information it contains should be useful for most Chinese laser cutters.

Larger Chinese models have higher quality, and function on basically the same principle ( except they use external stepper motor drivers ).

There is a more general guide: the Laser Cutter Guide. You should read it before you read this guide, as it contains much information you need to be familiar with to do things properly.

This guide is based on Stephane BUISSON’s blue box build log.

Safety

Lasers will make you blind

In an instant. In the blink of an eye, quite literally.

Never look into the beam or at any surface the beam might reflect off of.

Never have the machine powered while the door is open.

You are responsible for your own safety.

Eyes cannot be replaced.

Work on lasers should be done by informed and well trained professionals, in safe environments. There are no second chances here, if you are not trained, get help from a professional.

Eye protection of insufficient quality is sold very commonly, test your eye protection by firing the laser at it to make sure it’s actually capable of what it claims.

Eye protection alone isn’t enough, laser safety is an ensemble of procedures, knowledge and attention that must be paid. Improvisation has no place here.

Always make sure fire extinguishers of the adequate type are present on site.

A bucket of sand and a mini-shovel (which does not replace a fire extinguisher) can be a good tool to extinguish small “paper” fires in the machine without having to waste a fire extinguisher or wet the machine’s internals.

Door Safety Switch

If the machine does not come with a switch on the door that turns the laser off when the door is open, this is stupid and dangerous.

Please install that switch, and make sure it operates properly on a regular basis.

Fire Hazard

If you leave your machine alone even for a few minutes, fire can start.

They can burn your house, and they can burn your eyes. Be careful and never leave your laser unattended.

For more information on laser safety, please refer to laser safety resources.

Safety Warnings

Before you start wiring your machine’s elements to the board, there are several things you need to keep in mind and be careful about during all of the assembly.

Make sure you read this. Seriously. Not kidding. Do it. It’s important.

Polarity

Always make sure the polarity is correct when wiring in power inputs (coming from the Power Supply). Reversed polarity can damage or destroy all or part of your board.

Polarity is indicated on the board itself by the + and - signs. Double check.

On older versions of the board, markings are partially hidden by the connector, making it confusing. Rely on only the diagrams.

How to check polarity: Attach your multimeter probes to the two wires of your power source respectively. If the voltmeter reading is positive it implies that the red probe is connected to the positive wire (+) and the black probe to the negative wire (-).

The main (labeled VBB) power input has a reverse polarity protection, however, it will not hold forever. As soon as you notice something is wrong, turn the power supply off and check again.

Disconnecting Stepper Motors

Never disconnect or connect stepper motors from the stepper motor drivers while the board is powered (i.e., when the Power Supply is turned on).

The drivers have very good protection against most possible problems and are very hard to destroy accidentally. But it is possible.

Preventing Shorts

Be careful that nothing metallic ever touches the board while it is powered on. Falling screwdrivers, nuts and bolts can cause shorts and destroy the board.

- Check the board before powering it on

- Do not press the reset button with anything metallic, as you could slip and cause a short

- Use a plastic screwdriver or the like

Using the Right Connector

Always check the schematic before connecting power sources (coming from the Power Supply) to the board. Connected to the wrong connector can destroy components.

A common example of this problem is plugging a power input cable into the connector for an output, or plugging the limit switches in backwards.

Crimping Quality

Make absolutely sure of your connections using crimps or screw terminals, from wires to any type of connector, are very careful and well done.

Connections (to the stepper motors for example) lost while the machine is running can destroy your board.

VBB Power Input Markings

In the case of the VBB power input, be careful. If your board came with connectors pre-soldered, the 5mm connector is present, and the polarity of that connector is that of the large traces in the wiring diagram to the right (red is +, blue is -).

On some boards, the marking on the boards may be hidden by the connector itself, so for VBB, do not rely on the markings on the board, but on the diagrams on this page.

However, if you did not get your connectors soldered, and want to solder a 3.5mm connector instead of a 5mm connector, also note that the polarity is the opposite.

USB vs Ethernet

USB can, in some setups, be subject to interference, which causes disconnections, and can ruin your work. This is very hard to prevent if it happens even in normal conditions.

Ethernet, on the other hand, does not have this problem: save yourself the trouble, and use Ethernet right away. It's very nice. See Network for information on how to set it up.

How to Destroy Your Board (Don’t Do These Things)

If you receive a bad board, you will get a replacement. But if you destroy your own board, your only options will be to fix it yourself (which can be quite difficult), or get a new one.

This is why it is very important you make sure you do not destroy your own board. Smoothieboard is reasonably protected, but there are still things that will destroy it.

The general idea is: if a part of the board gets too much power, it will get destroyed.

Common mistakes that cause board destruction:

- Plugging 12-24v (motor power) into anything you are not supposed to. Like the 5V line, or an end-stop or thermistor input for example. Problems with the 5V or 3.3V power are not as much of a problem as the board is 5V-tolerant, so wrong connections and shorts should be okay as long as they do not last too long.

- Shorting 12-24v to anything else, which is essentially the same as plugging it into a place you are not supposed to (see above). This can happen by dropping a metal object onto the board, bad soldering, loose wires, un-protected wires, etc ...

- Using an inductive load (like a motor, fan or solenoid) on a MOSFET, without a diode across (see Fan documentation).

The general idea here is: always make sure everything is clean, and double-check everything before turning the power on. You can not learn by making mistakes here, as mistakes will likely cost you your board.

Electrostatic discharge can also destroy your board: make sure you properly ground everything.

Heater Safety

If your machine contains any heating element and uses the temperature control module to control it, please make sure you read the section about implementing all safety measures here, and implement as many as you can.

Fires will kill you if you don't.

Grounding

Make sure your machine's case and electronics are properly grounded, also make sure your location's electrical installation's grounding is correctly done.

Grounding Resources:

Environmental Hazards

It's not just the machine itself that can be dangerous:

Laser Cutters: The machine vents large quantities of toxic smoke and gas, make sure it is very well evacuated to a place where no-one is breathing them

CNC Mills: Dusts, like wood dust for example, can be explosive if they come in contact with a flame, be careful and take measures to limit dust in the air

3D Printers: The acetone used to clean things is very flammable, and the sprays used to increase bed adherence are explosive, store them adequately and be careful when using them

Confined Spaces: You are even more in danger if you are using your machine in a confined space, always be on the watch for safety issues.

Further Reading

For a good read about safety, you can refer to the RepRap Wiki documentation on the subject.

To properly understand some of the safety instructions in this documentation, basic knowledge about electricity is required. See this page for a refresher on the basics.

Summary

- Always check polarity before connecting power

- Never disconnect motors while powered

- Keep metallic objects away from powered boards

- Double-check all connections before powering on

- Ensure quality crimps and connections

- Use Ethernet instead of USB when possible

- Implement all heater safety measures

- Properly ground your machine and workspace

- Be aware of environmental hazards

- When in doubt, power off and check

Remember: Prevention is always better than repair. Take your time, double-check everything, and never skip safety steps to save time.

It is highly recommended to integrate a door safety interlock to prevent the laser from firing when the enclosure is open. The laser PSU provides a safety switch connection (P or WP pin) that must be connected to ground for the laser to fire. Connect this pin through a normally-open door switch so the circuit is only completed when the door is closed. This provides hardware-level protection independent of software controls.

Inside the machine

If you look into your machine, you will see two main electronics items:

The power supply

The laser Power Supply ( PSU ) converts the mains ( 110 or 220V AC ) power into very high voltage ( several thousand volts ) that is fed to the laser CO2 tube.

In the case of these small blue box laser cutters, this PSU also provides 5V power for the electronics’ logic, and 24V for the stepper motors.

The exact model may vary depending on your exact machine’s model, manufacturer, and version. Here in this tutorial, we will be using the MYJG40W from Amazon, but other PSUs should be very similar in their wiring and function.

If your PSU is too different from the one in this guide to allow you to adapt the instructions, please contact the community.

Here are the various connections you will find on your PSU:

| Connector | Connection label | Name | Description |

|---|---|---|---|

| High power | L- |

Mains Ground | Connects to the mains ground wire and to the enclosure for grounding |

FG |

Laser Ground | The ground side of the tube connects to this connection | |

AC |

Mains | Alternative current from the mains cable | |

AC |

Mains | Alternative current from the mains cable | |

| Logic | G |

Logic Ground | Common ground for all logic signals |

P or WP |

Safety switch | The laser won’t fire unless this is connected to Ground, used for the door switch | |

L or TL |

Fire switch | The laser will fire if this is connected to Ground, used for the test switch | |

G |

Logic Ground | Common ground for all logic signals | |

IN |

Input | Reads an Analog or PWM signal to set the laser’s power | |

5V |

Logic power | 5V to power the controller board’s logic | |

| Low power | +24V |

Motor power | 24V to move the stepper motors |

G |

Power Ground | Common ground | |

5V |

Logic power | Unconnected | |

L |

? | Unconnected |

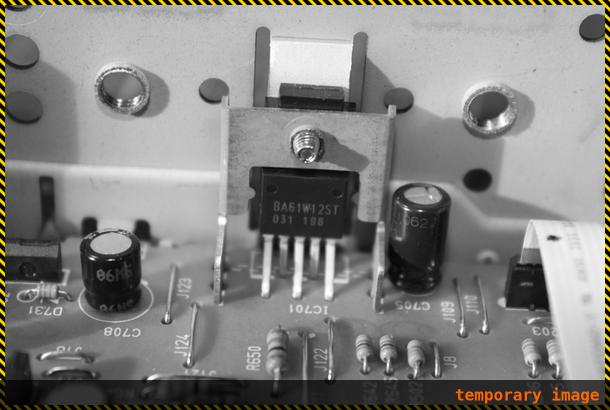

The controller board

The controller board connects via USB to your computer, receives data ( like an image to engrave ), and controls both the stepper motors and the laser power, to obtain the desired result ( an engraved image ).

The controller board that comes with the blue box is very limited, and can only interface with the crappy closed software that comes with it. This is essentially why you are reading this guide: the goal is to throw this board out, and replace it with a Smoothieboard.

Basic power

First things first, you need to provide power to your Smoothieboard.

There is a 4-pin 5mm connector on your Smoothieboard with a VBB/GND and 5V labels.

You will want to connect 24V power to the VBB input on the Smoothieboard, 5V power to the 5V input on the Smoothieboard, and ground to GND:

| Connector | Connection label | Name | Description |

|---|---|---|---|

5V |

Logic power | Connect to the 5V power input on Smoothieboard | |

+24V |

Motor power | Connect to the VBB power input on Smoothieboard | |

G |

Power Ground | Connect to the Ground input on the Smoothieboard |

Once this is wired, if you power the laser PSU, the Smoothieboard should turn on, and both the red VBB LED, and the orange 3.3V LED should light up.

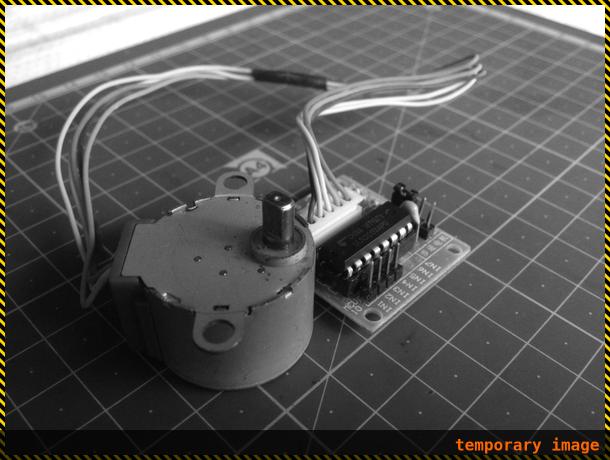

Controlling the stepper motors

Your machine has two stepper motors, one for the X axis, and one for the Y axis. Each motor has 4 wires, controlling two internal coils.

If you are using a Smoothieboard in a blue box, you will want to wire each of those stepper motors to one of the stepper motor drivers on the Smoothieboard ( M1 for X, and M2 for Y ).

If you are following this guide along but are using a larger machine than the blue box, then it’s very likely your machine came with external stepper motor drivers, and you want to simply have Smoothieboard control those via their step/direction/enable interface. If this is the case, please look at the laser cutter guide’s section on external stepper motor drivers.

The first thing you want to do, is find the wires for each stepper motor, and follow them to the controller board.

Once you have located each set of 4 wires, separate them from the rest, and for each, make a 4-pin connector using the connectors and crimps that came with the Smoothieboard.

Note: The stepper motor wires come on ribbon cables, and are arranged in a specific order. You need to keep that order when connecting them to the Smoothieboard, you cannot connect them in a random order. If you lost the order, look at the laser cutter guide, it has detailed information on how to figure this out.

Then connect the X stepper motor to the M1 stepper motor driver, and the Y stepper motor to the M2 stepper motor driver.

Motor Configuration:

In your configuration file, set the motor current and steps per mm:

alpha_current 1 # X stepper motor current (1 Ampere)

beta_current 1 # Y stepper motor current (1 Ampere)

alpha_steps_per_mm 157.575 # Steps per mm for X axis

beta_steps_per_mm 157.575 # Steps per mm for Y axis

In your configuration file, set the motor current and steps per mm:

[current control]

alpha.current = 1 # X stepper motor current (1 Ampere)

beta.current = 1 # Y stepper motor current (1 Ampere)

[actuator]

x.steps_per_mm = 157.575 # Steps per mm for X axis

y.steps_per_mm = 157.575 # Steps per mm for Y axis

Once this is done, connect to the board via USB using software such as Pronterface or the web interface, power up the machine, and you should be able to move the stepper motors, and therefore the axes, using the controls in the software.

Testing Laser Firing Safely

Before testing laser firing, ensure proper eye protection is worn by all persons in the area, the enclosure is closed, and the area is clear of flammable materials. Never look directly at the laser beam or reflections. Always have a fire extinguisher nearby.

After configuring your laser power control (see the Laser Cutter Guide for detailed laser configuration), you can test laser firing using G-code commands:

Basic Test Commands:

M3 S0.1 # Turn laser on at 10% power (S value from 0.0 to 1.0)

M5 # Turn laser off

Testing Procedure:

- Start with very low power settings (S0.05 to S0.1)

- Place a piece of dark material (cardboard or wood) in the cutting area

- Ensure enclosure is closed and all safety interlocks are engaged

- Send

M3 S0.1to fire the laser at 10% power - Observe the laser spot on the material (should see a visible dot)

- Send

M5to turn the laser off immediately - Gradually increase power in small increments (S0.1, S0.2, etc.) to verify power control

LightBurn Integration

LightBurn is a popular commercial laser cutting software that works excellently with Smoothieware-based laser cutters. It provides an intuitive interface for designing, importing, and cutting projects.

Setting up LightBurn with Smoothieboard:

- Download and install LightBurn (free trial available)

- Connect your Smoothieboard via USB

- In LightBurn, go to Devices → Find My Laser

- Select your Smoothieboard from the detected devices

- Choose Smoothieware as the device profile

- Configure your working area dimensions (approximately 300mm x 200mm for blue box machines)

Key LightBurn Features:

- Visual job preview and positioning

- Layer-based power and speed control

- Built-in design tools and image import

- Real-time position feedback

- Job time estimation

- Support for multiple file formats (SVG, DXF, AI, PDF, images)

Recommended Settings:

- Set your maximum feed rate to match your configuration

- Configure laser power range (0-100% mapped to your S value range)

- Enable “Start from current position” for easier job alignment

- Use the frame function to preview cut boundaries before firing

For detailed configuration instructions and advanced features, refer to the LightBurn documentation and the Laser Cutter Guide on this site.